Salt spray test is a common and crucial accelerated aging test, which is applied in fields such as metal surface treatment, coatings, electroplating, automobiles, electronics, aerospace, etc.

But do you know? Salt spray testing is not "a universal solution", but rather encompasses various types. Different kinds of salt spray test chambers are suitable for different materials and test targets. This article will guide you to quickly understand the differences and applications of various types of salt spray test chambers.

The most common and fundamental type of salt spray test complies with international standards such as ASTM B117.

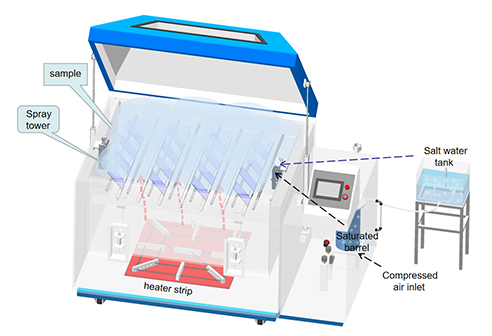

Test principle: A 5% sodium chloride solution is atomized through a spray device and continuously sprayed onto the sample to be tested, with the temperature maintained at 35℃.

Scope of application: Electroplated parts, coatings, galvanized sheets, stainless steel, etc.

Advantages: Simple operation, standardized and mature, suitable for comparative tests.

Disadvantage: It is quite different from the actual natural corrosion environment and is only used for the preliminary screening of the anti-corrosion performance of materials.

A more "aggressive" test type than neutral salt spray, it is mostly used for corrosion verification of high-end anti-corrosion coatings and aluminum alloy parts.

Test principle:

ASS: Add glacial acetic acid on the basis of NSS to adjust the pH of the solution to 3.1-3.3.

CASS: Adding copper chloride to ASS intensifies corrosion.

Scope of application: copper-nickel-chromium multi-layer electroplated parts, automotive marking parts, precision hardware parts.

Advantages: Accelerate corrosion more rapidly and assess the ultimate capacity of high-corrosion-resistant coatings.

Recommended equipment: LIB-S series salt spray test chamber, which can conduct various tests such as NSS, ASS, CASS, etc. It supports fully automatic tests of ASTM B117 and ISO 9227.

The whole machine is made of one-time formed fiberglass reinforced plastic, which is acid-resistant, highly stable and has a long service life.

It simulates the real corrosion process of "salt spray + drying + damp heat + condensation" alternating in the natural environment, which is closer to the actual usage conditions.

Test principle: During one test cycle, the sample undergoes multiple environmental stages, such as salt spray → drying → wet heat condensation → re-spraying, forming a cycle.

Scope of application: Automotive industry (such as body parts, chassis parts), Marine equipment, electrical cabinets, outdoor facilities.

Advantages: The test results have more practical reference value and are gradually becoming the mainstream trend in the industry.

Standards: ISO 16701, VDA 233-102, SAE J2334, etc.

✅ Recommended equipment: LIB-CCT cyclic corrosion test chamber, supporting multi-stage programming, custom condition simulation.

Test type | Simulated environment | Recommended application | Typical standard |

NSS | coastal or humid areas,primary corrosion | Electroplating, spraying, basic anti-corrosion test | ASTM B117 |

CASS | acid rain | highly polluted environment | ISO 9227 ASS/CASS |

CCT | Natural weather, full process | Automotive, outdoor equipment | SAE J2334、VDA 233-102 |

If you are not sure about your testing standards or industry requirements, please feel free to contact the LIB team for professional selection suggestions.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español