Against the backdrop of the rapid development of the new energy industry, the demand for lithium battery testing is increasing day by day, especially for performance verification in extreme environments. Common battery testing is thermal cycling testing, and relevant standards include IEC 62133-2-2017. UL 1642-2015 Clause 17, Clause 18, UN 38.3, GB31241-2014, etc. The tests of these standard values will involve high temperatures.

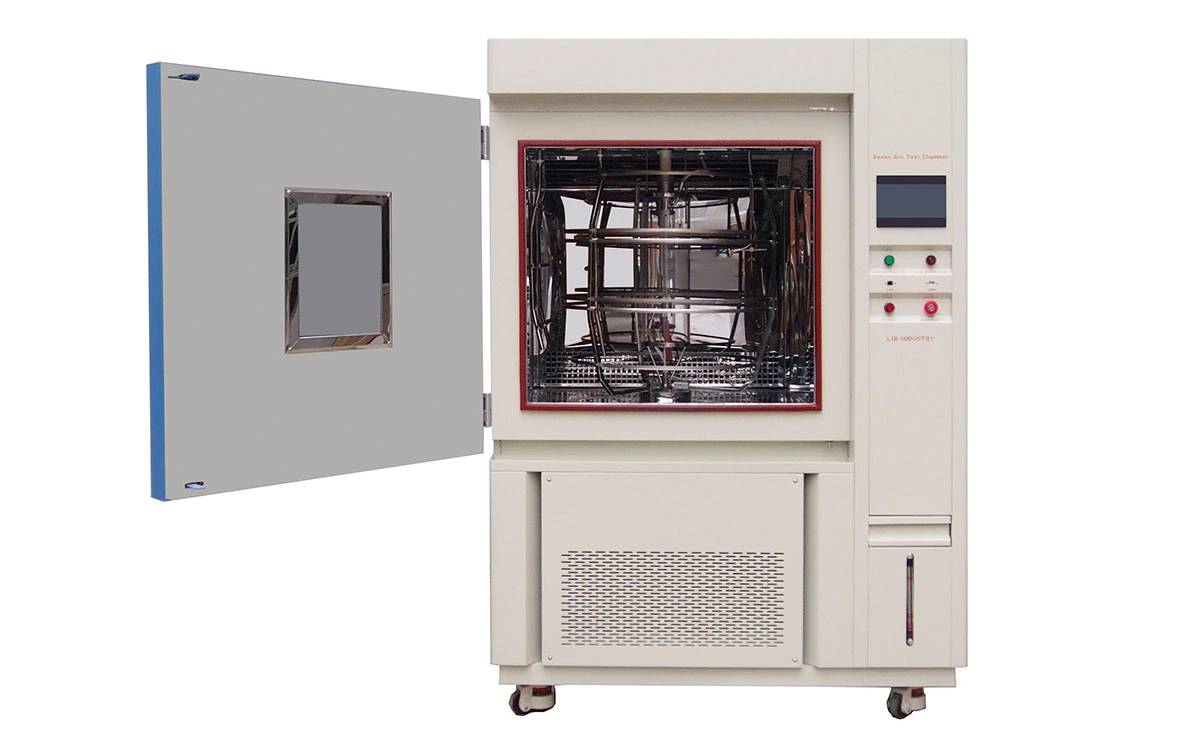

Due to the potential risks of thermal runaway, gas leakage and even explosion that may occur during battery testing processes such as charging and discharging, high and low temperatures, and overcharging, the safety design of battery testing chambers is of vital importance. LIB integrates multiple safety protection technologies on battery test chamber to build a complete set of reliable and efficient safety protection systems, ensuring the safety of personnel and equipment during the testing process.

Model | TR10-1000C | |

Overall Dimension (mm) | 2120*1200*2100 | |

Interior Volume | 1000L | |

Parameters | Temperature Range | C : -70℃ ~ +170 ℃ |

Temperature Fluctuation | ± 0.5 ℃ | |

Temperature Deviation | ± 2.0 ℃ | |

Cooling Rate | 10 ℃ / min (average) | |

Heating Rate | 10 ℃ / min (average) | |

| ||

The LIB battery test chamber adopts an explosion-proof design in structure, which is reflected in the following aspects:

Chamber exterior material: The test chamber is made of thickened A3 steel plate, which has excellent pressure resistance and impact resistance, ensuring that it can withstand the explosion impact of batteries. Meanwhile, there is a buffer space between the shell and the internal structure, which can further absorb the explosion shock wave.

Door explosion-proof lock: Equipped with heavy-duty explosion-proof door hinges and high-strength lock structures, even if a minor explosion occurs inside, it can prevent the door body from deforming or bouncing away.

Observation window protection: The observation window is made of multi-layer tempered glass and is equipped with explosion-proof film to ensure that no glass splashes and injuries occur in the event of an explosion.

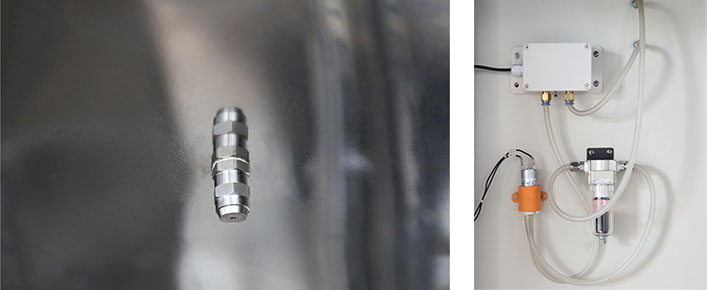

The high-temperature and high-pressure damage caused by battery thermal runaway. The LIB test chamber is equipped with a pressure relief system:

Automatic pressure relief valve: When the pressure inside the chamber exceeds the set threshold, the pressure relief valve automatically opens to quickly release the excessive air pressure and prevent the chamber from bursting.

Pressure monitoring system: It collects pressure data inside the chamber in real time. Once it approaches the warning value, the system will automatically stop the test and trigger an alarm prompt.

Automatic fire extinguishing device: It can be integrated with gas fire extinguishers or water mist fire extinguishing modules. Once the smoke sensor detects an abnormality, the sprinkler system will immediately start working to extinguish the fire. The smoke produced by the fire will also be discharged in time.

The LIB battery test chamber is equipped with a self-developed PLC+ touch screen control system, which realizes the automation of safety management through a software platform.

Alarm linkage mechanism: When data such as pressure, gas, and temperature are abnormal, the system will automatically interrupt the test and link the sound and light alarm and remote push.

Historical data tracking and backtracking: All abnormal records can be traced and viewed, facilitating post-event analysis and management.

Remote control interface: Supports remote monitoring and operation, allowing real-time grasp of equipment status and enhancing the safety level of experiments.

The LIB battery test chamber builds a multi-level safety protection system through comprehensive measures such as explosion-proof structure, intelligent pressure relief system, electrical protection and intelligent interlocking control. For detailed parameters, selection suggestions or customized services of the LIB battery test chamber, please feel free to contact our professional engineering team.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español