With the continuous improvement of vehicle quality standards, traditional vertical xenon arc chambers have gradually revealed their limitations: small size, uneven illumination, and inability to cover complete lamps or large components inside the vehicle, resulting in significant deviations in test results. Especially in the face of vehicle-level testing requirements, enterprises urgently need a solution that can not only simulate real environments but also accommodate large-sized samples.

To this end, LIB has a Walk-in Xenon Arc Chamber , which provides a one-stop platform for triple aging tests of light, temperature and humidity for automotive lamps, interiors, plastic parts, etc.

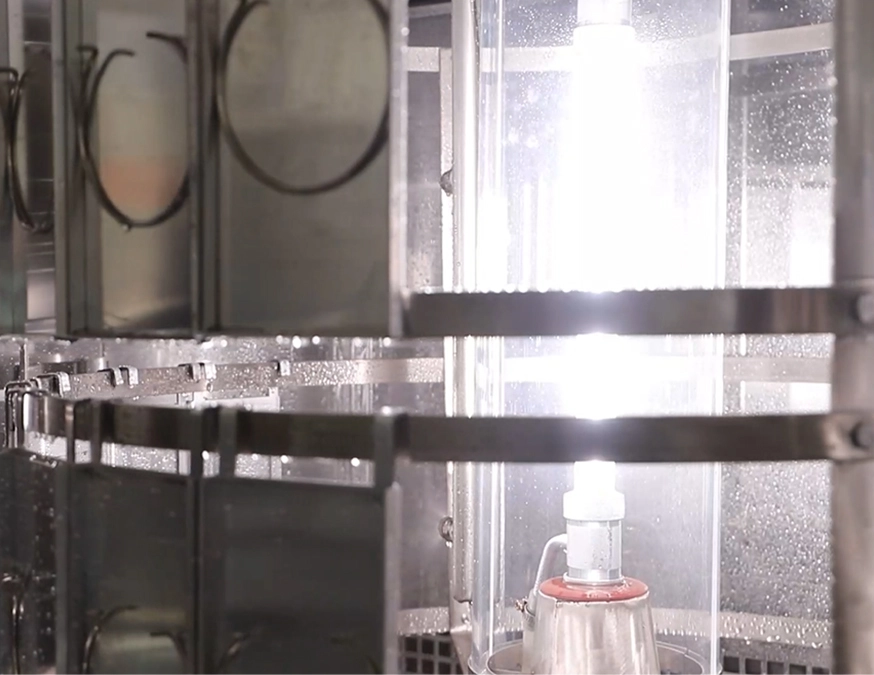

When cars are exposed to sunlight for a long time, ultraviolet rays (UV) can break the polymer bonds, causing fading and cracking. The high temperature brought by infrared rays accelerates thermal aging. Moisture and condensation will further accelerate the deterioration of seals and transparent covers. These factors do not occur independently but act in superposition, forming a complex "composite stress aging" environment.

The LIB walk-in xenon arc chamber integrates light, temperature and humidity control, capable of reproducing natural aging processes such as day and night alternations, high-temperature exposure and moisture condensation, providing more scientific data support for material reliability testing.

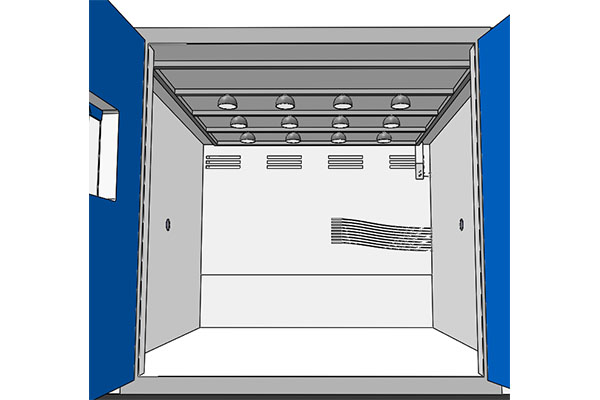

The LIB test chamber supports customizable workspaces ranging from a few cubic meters to tens of cubic meters, easily accommodating large structural components such as headlight systems, central control instruments, and door interiors. It can even conduct local vehicle tests, significantly enhancing the verification dimension.

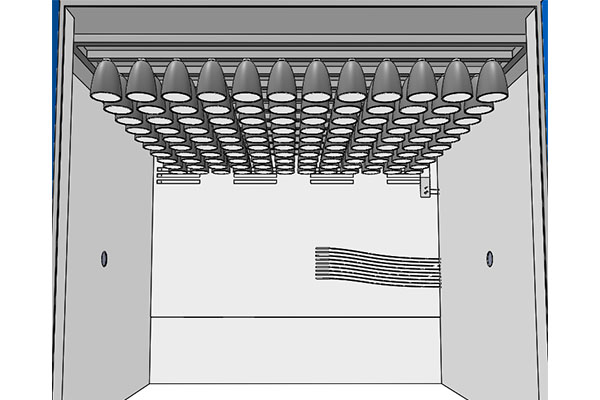

The walk-in xenon arc chamber shown in the picture is equipped with 20 xenon lamps. The lamp tubes are evenly arranged and combined with a reflection design to ensure consistent illuminance in all areas.

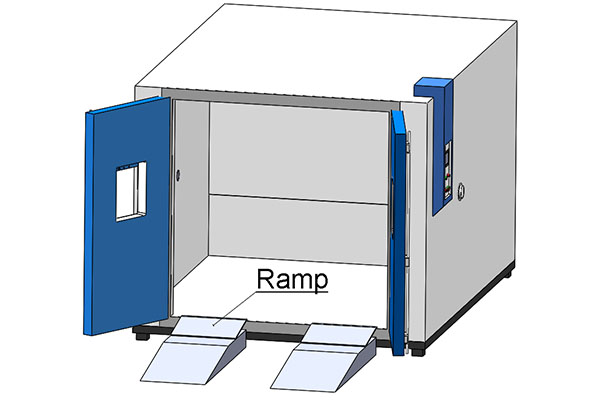

LIB offers a design with ramps or tracks, allowing it to be directly pushed into vehicle bodies or heavy samples. It supports rapid positioning and flexible arrangement, significantly enhancing testing efficiency.

The system supports standard test procedures (such as ISO 4892-2, ASTM G155, etc.), and can flexibly set the light cycle, wet heat cycle, and condensation process, truly achieving all-weather accelerated aging tests at the vehicle level.

Each walk-in xenon arc chamber is a tailor-made solution for the customer. LIB offers full-process engineering services, from requirement research, solution design to equipment manufacturing and commissioning, ensuring that every detail fits your test scenarios:

The workroom size is customized as needed

Personalized design of the quantity, type and arrangement of the lamp tubes

The structural modules such as the floor, sample rack and lighting window can be flexibly configured

Expandable remote control, data export, and cloud platform integration functions

Whether you are an original equipment manufacturer , a new energy vehicle manufacturer, or a supplier of automotive lighting and interior materials, LIB can create a professional, standardized and replicable environmental simulation platform for you.

LIB is well aware that testing equipment is a long-term investment. Therefore, we provide each customer with:

Follow up on the entire project

On-site installation and commissioning + operation training

3-year complete machine warranty + lifetime technical support

7× 24-hour response mechanism

In addition, LIB also offers periodic maintenance services and functional upgrade suggestions to ensure that your device always operates efficiently and stably, and continuously meets the testing requirements of new standards and new projects.

Contact us immediately to get a customized solution and a free technical assessment!

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español