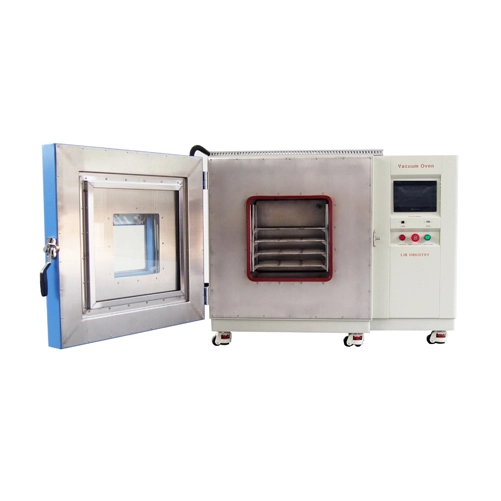

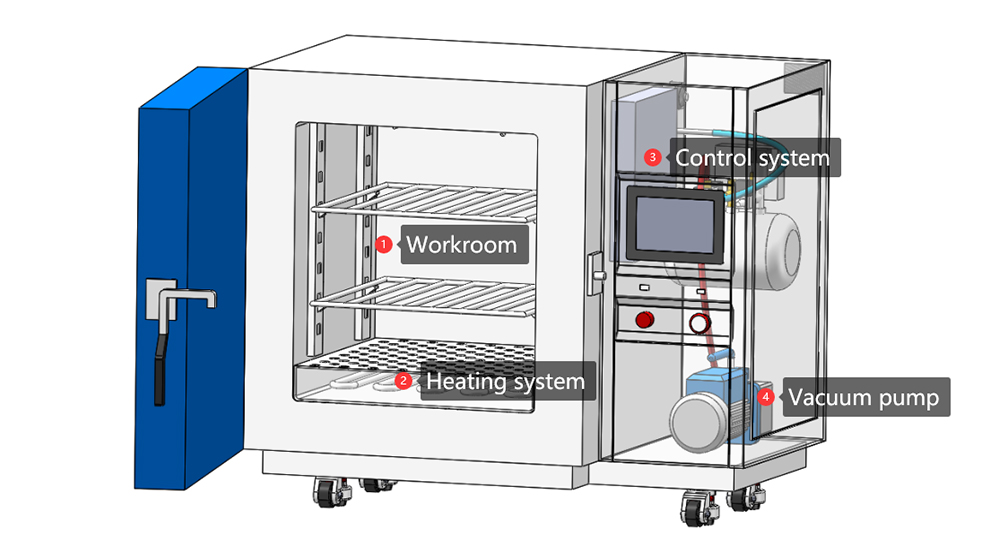

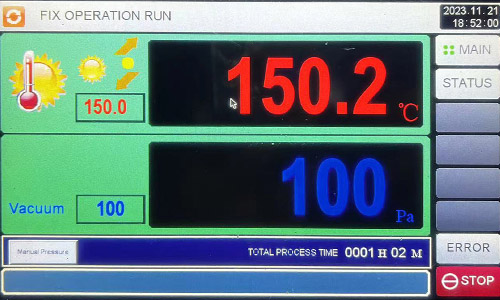

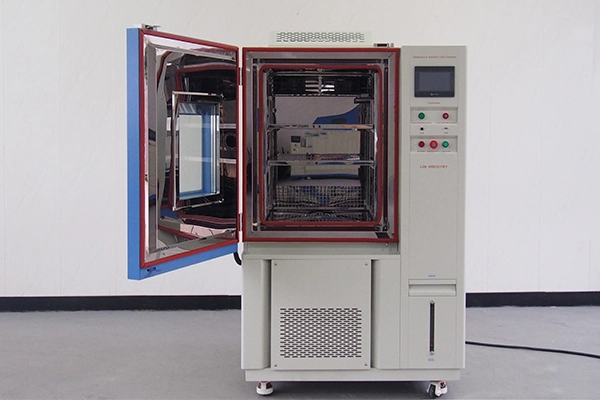

LIB Industrial Vacuum Oven is used for plating, desiccating, out gassing, sterilization, or drying application needs in vacuum. Quick shipping with 50L, 100L to 200L standard models, this can support customer to use timely. The size, volumes, workroom structures and special sample holders can be customized.

Model:VO-20,VO-30,VO-50,VO-90

Standard:IEC 60216, MIL-811F

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español