Altitude Chamber Features and Benefits

1. The altitude chamber is a comprehensive environmental stress test chamber that combines temperature, humidity, and low air pressure.

2. The altitude simulation chamber can achieve atmospheric pressure ~ 0.5kPa pressure test conditions in the high altitude test chamber.

3. From obtaining customer needs, to discussing solutions, production, transportation, installation and commissioning, LIB can realize one-stop solutions.

4. LIB team responds quickly, has high work efficiency and can delivery the chamber as soon as possible.

Altitude Chamber Specifications

Model | A-1000 |

Internal dimensions | D 1500 W 1000 H 970 mm |

External dimensions | D 2050 W 1300 H 2200 mm |

Temperature range | —40℃ to +150℃ |

Humidity range | 20% ~ 95% (more than 50Kpa can be controlled) |

Temperature fluctuation | ≤ ±0.5℃ |

Temperature deviation | ≤ ±2.0℃ |

Temperature uniformity | ≤ 2.0℃ (under normal pressure and no load) |

Heating rate | 3℃/min |

Cooling speed | 2℃/min |

Pressure range | Atmospheric pressure to 0.5kPa |

Pressure deviation | ± 2Kpa |

Depressurization time | Atmospheric pressure to 0.5k ≤30min |

Pressure enclosure | Manganese steel, surface spray treatment |

Other outer wall materials | Double-sided galvanized steel plate, surface spray treatment |

Inner wall material | SUS304 stainless steel plate |

Vacuum system | Vacuum pump, air pumping regulating valve, inflation regulating valve |

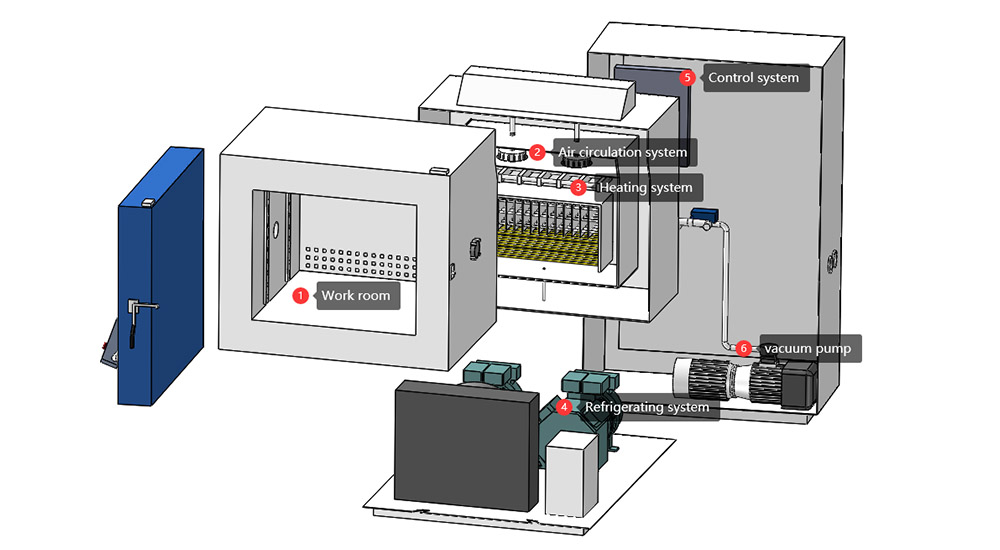

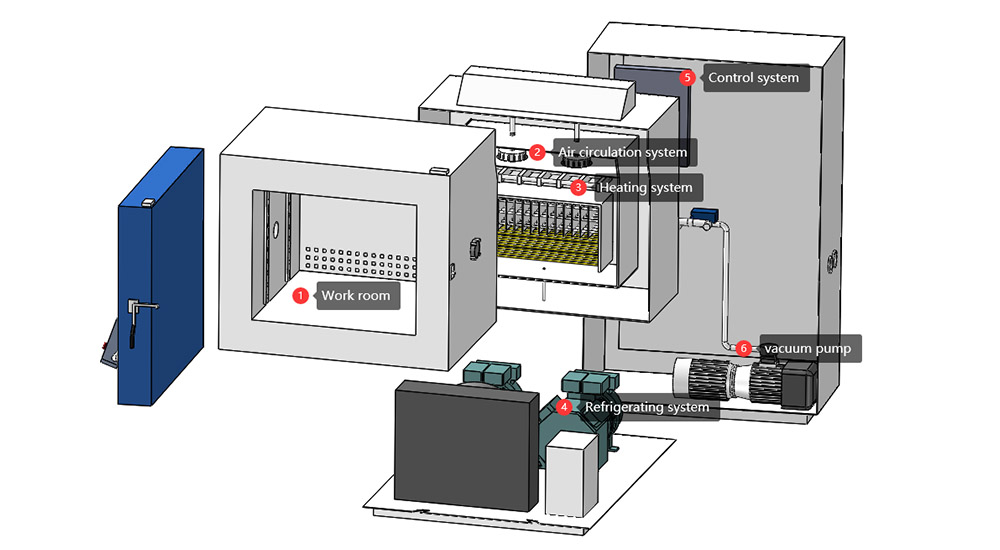

Configuration of Altitude Chamber

① Workroom |

Workroom is made of 304 stainless steel plate. Double punched sample holder, standard bearing capacity 50kg. There is a 50mm diameter cable hole on the left side of the workroom to energize the test piece.

|  |

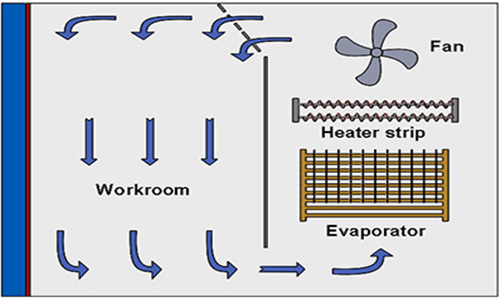

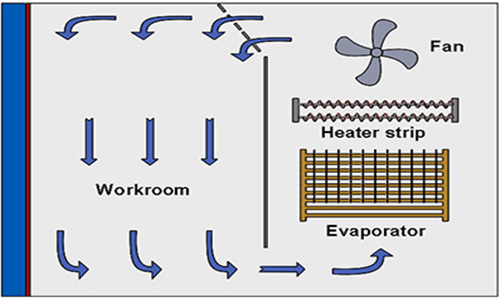

② Air circulation system

| High altitude test chamber is composed of air inlet, air outlet and fan. The fan ensures the uniform distribution of air and the stability of environmental parameters. |  |

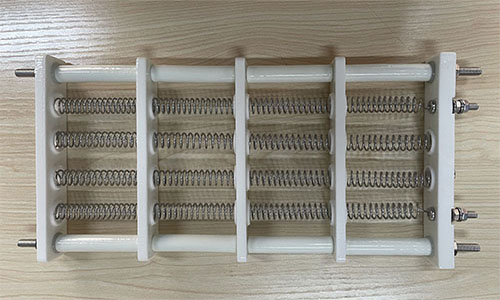

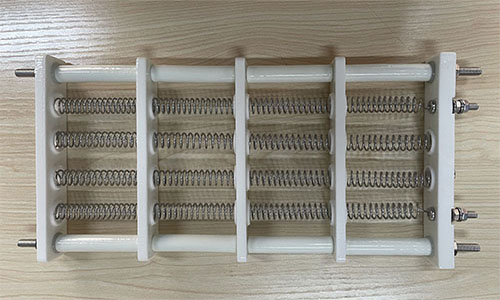

③ Heating system | Contains heating wire and temperature sensor. The temperature rise rate can reach 3℃/min. |  |

④ Refrigerating system | Compressors, evaporators and other refrigeration equipment. The temperature cooling rate is 1℃/min. |  |

⑤ Control system | Set simulation conditions through the console, automatically adjust parameters such as pressure and temperature, and record and analyze operating data.

|  |

⑥ Vacuum pump | Key component of the pressure regulation system and reduces the air pressure by draining part of the workroom air to simulate the high altitude low pressure environment. | .jpg) |

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español

.jpg)