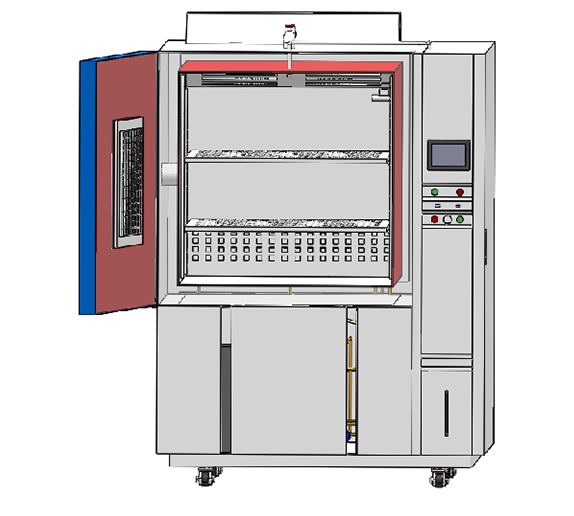

Battery Test Chamber Features and Benefits

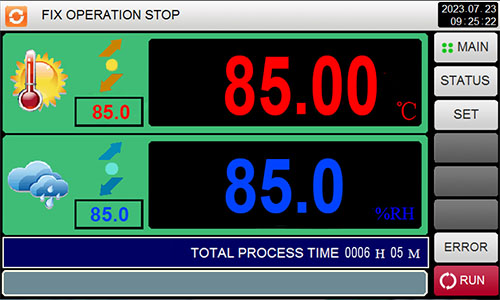

1. Wide temperature range (-70℃ to +150℃), temperature fluctuation ≤±0.5℃, Humidity control accuracy ±2%RH,the battery test chamber supports rapid temperature change (up to 5℃,10℃,15℃/min).

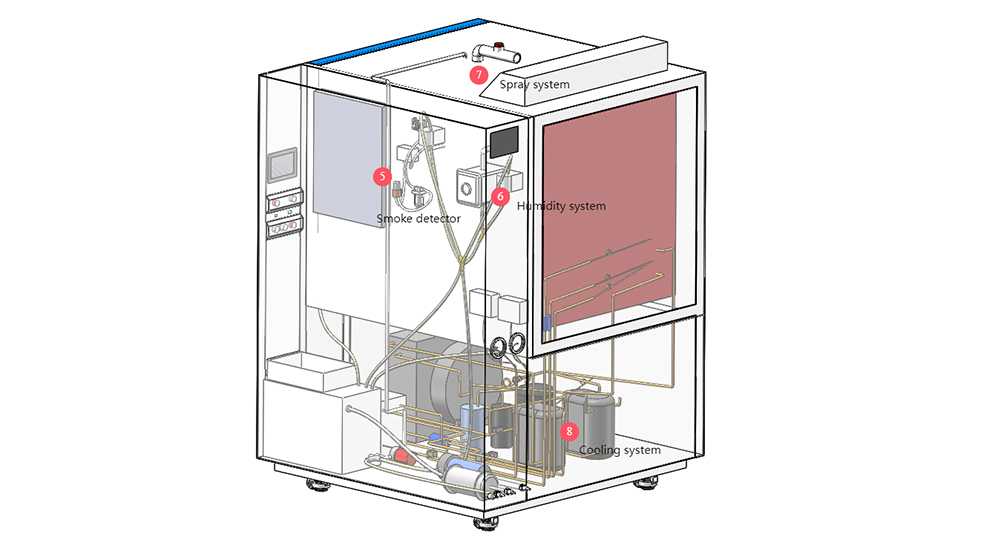

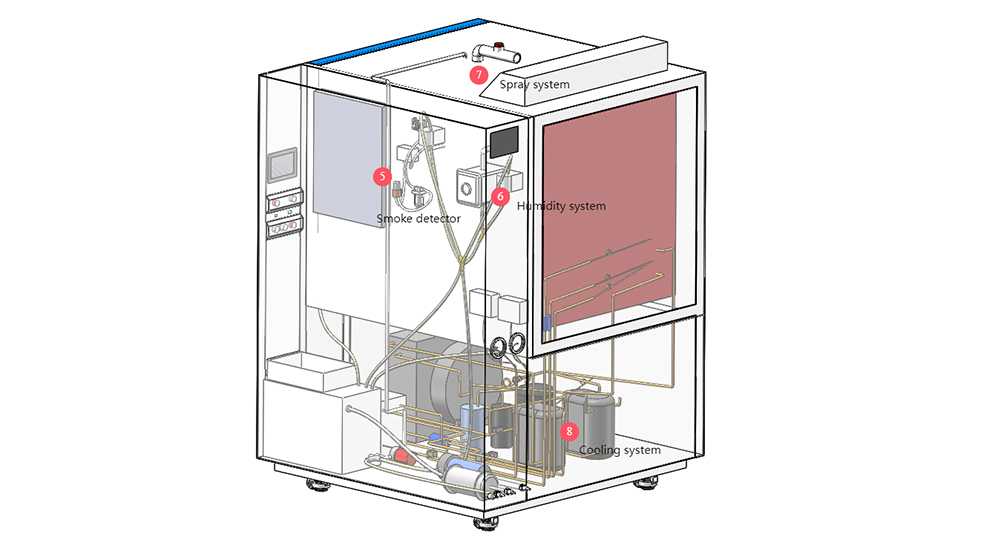

2. Three-level explosion-proof design (chamber explosion-proof layer + pressure relief channel + gas fire extinguishing device), real-time smoke/pressure/leakage monitoring, the controller automatically cuts off the power supply and remote monitoring and emergency shutdown.

3. PLC intelligent programmable controller, cloud storage of test data, automatic generation of test curves, automatic testing, reduce errors.

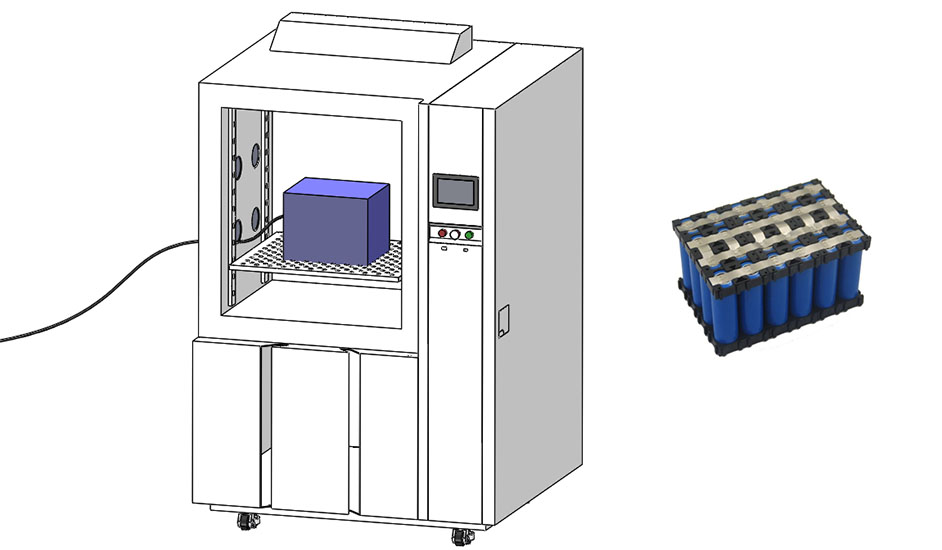

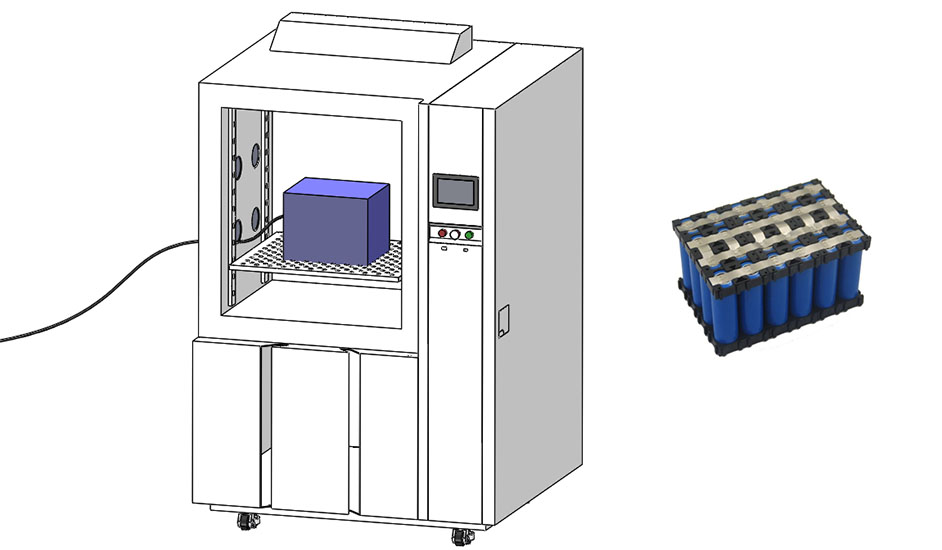

4. The workroom volume and size can be customized to support various shapes and sizes of cylindrical/square/soft pack batteries, and a variety of other solutions can be customized according to your needs.

Battery Test Chamber Specifications

Model | TR10-1000C |

Internal Dimension (mm) | 1000*1000*1000 |

Overall Dimension (mm) | 2120*1200*2100 |

Interior Volume | 1000L |

Parameters | Temperature Range | C : -70℃ ~ +170 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Cooling Rate | 10 ℃ / min (average) |

Heating Rate | 10 ℃ / min (average) |

How Does LIB Address the Security of Battery Testing?

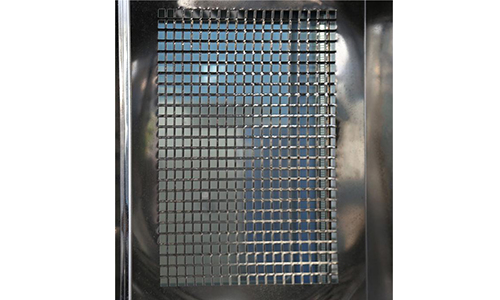

6mm reinforced workroom + observation window explosion-proof mesh + explosion-proof lock + smoke detection system (greater than 300PPM)/ pressure probe (greater than 200Kpa)+ spray system + smoke exhaust system

Configuration of Battery Test Chamber

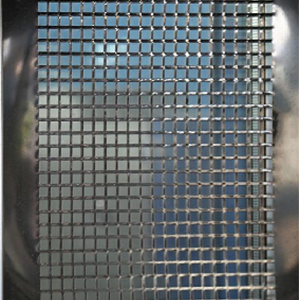

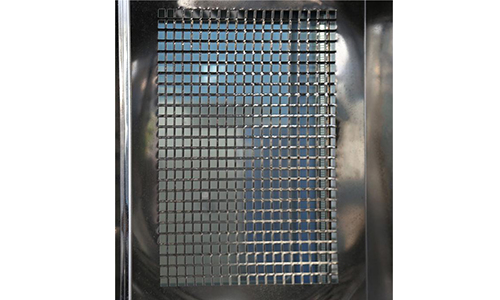

1. Workroom | SUS304 stainless steel plate, good sealing. Explosion-proof hinge and chain: connecting the door and the chamber, the explosion-proof chain prevents the door from flying out when the pressure in the chamber changes. Observation window with blast mesh. Movable shelving with adjustable height.

|

|

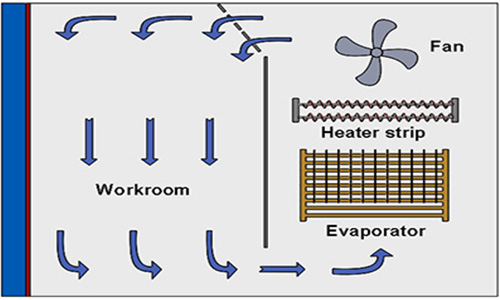

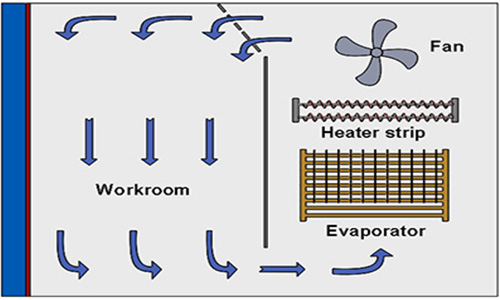

2. Air circulation system | The fan circulates the air in the workroom to ensure the uniformity of temperature and humidity parameters |

|

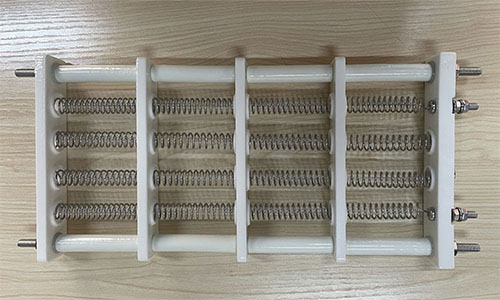

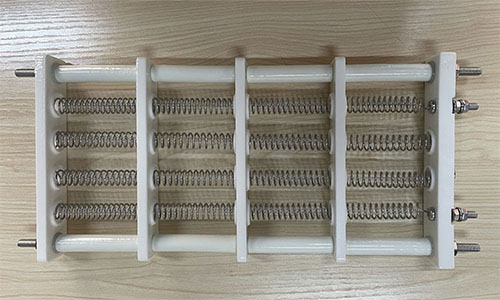

3. Heating system | Nickel-chromium alloy electric heater to achieve temperature inside the chamber. |

|

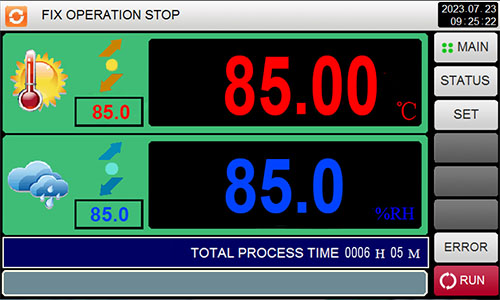

4. Control system | According to the feedback data of the sensor, the cooling and heating system and the humidity regulation device are accurately regulated to keep the temperature and humidity in the chamber stable. |

|

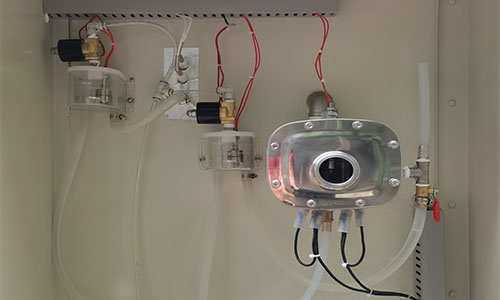

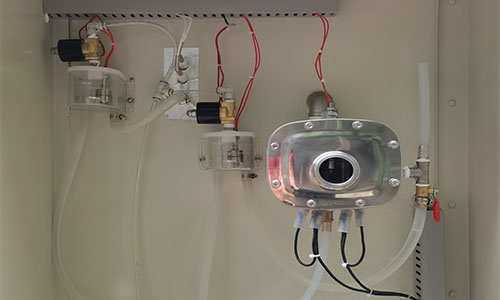

5. Smoke detector | Real-time monitoring of whether there is smoke in the battery test chamber, when the detection of smoke concentration reaches the set threshold, quickly send an alarm signal. |  |

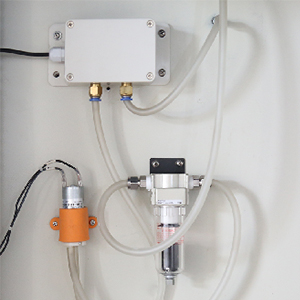

6. Humidity system | By heating evaporating water to increase the humidity of the air in the chamber. |

|

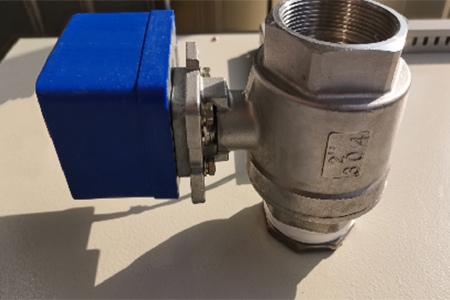

7. Spray system | When the smoke detector alarms and a fire is confirmed, spray water on the battery test chamber to cool down and prevent the fire from spreading. |

|

8. Cooling system | Composed of compressor, condenser, evaporator and so on to form a mechanical refrigeration cycle. |

|

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español