Features and Benefits of LIB Blowing Sand and Dust Test Chamber

1. Custom systems, the size and performance can be customized according to the customer's needs.

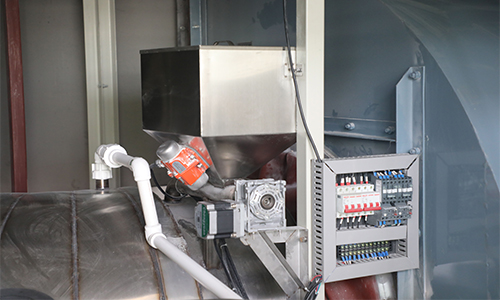

2. Automatically fill sand or dust, automatically distributes sand or dust over time. Automatic temperature & humidity control.

3. All these parameters can be programmed using the programmable colour touch screen controller, can be connected to the computer and the laboratory operating system, so as to achieve remote control.

4. After effectively communicating with the customer about the test requirements, the model can be accurately designed and the blowing sand test chamber can be delivered quickly.

Specifications of Blowing Sand and Dust Test Chamber

Model | DIM-1000 |

Internal Dimension | 1000*1000*1000mm D*W*H |

Overall Dimension | 3000*6100*2200mm D*W*H |

Interior Volume | 1000L |

Blowing Dust |

Air velocity | 1.5 -8.9m/s |

Concentration of dust | 10.7±7g/ m³ |

Dust particles | < 150μm |

Blowing sand |

Air velocity | 18.0 -29.0m/s |

Concentration of sand | 0.18+0.2g/m³; 1.1+0.3g/m³; 2.2+0.5g/m³ |

Sand particles | 149μm - 600μm, 600μm - 850μm |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Testing Platform Diameter | 600mm |

Door Lock | Electromagnetic lock |

Testing Platform Speed | 1-7 r.p.m |

Dust Detector | Integrated dust detector |

Exterior Material | A3 Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

Standard | MIL-STD- 810 |

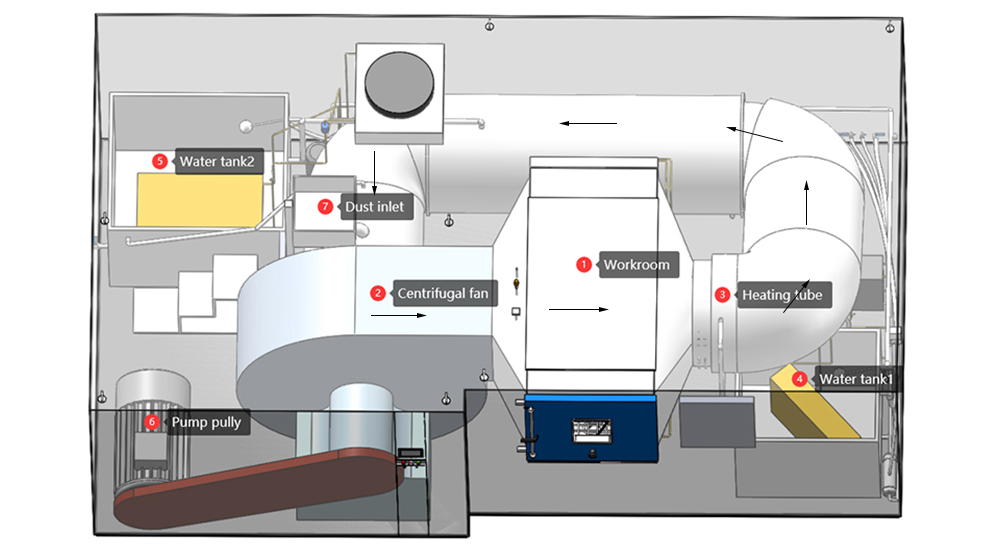

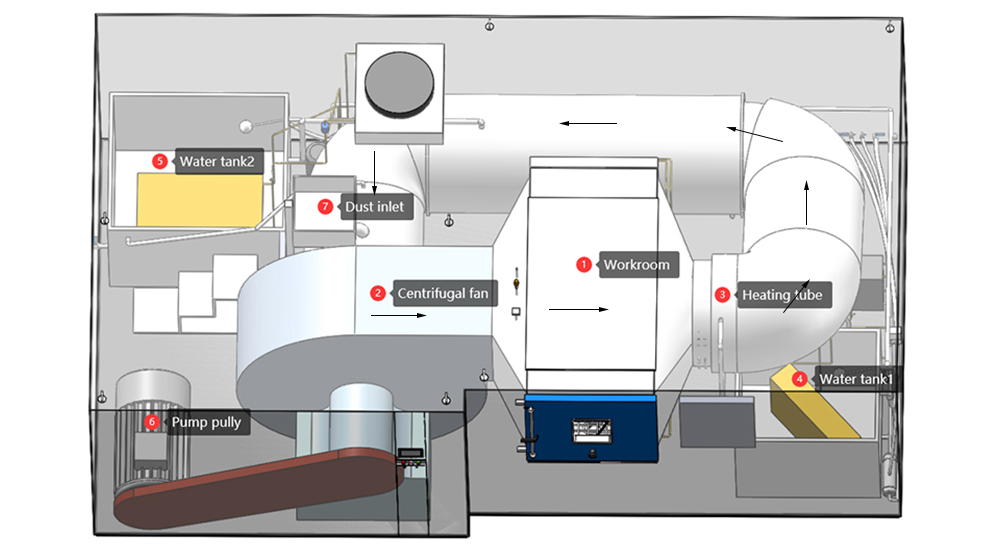

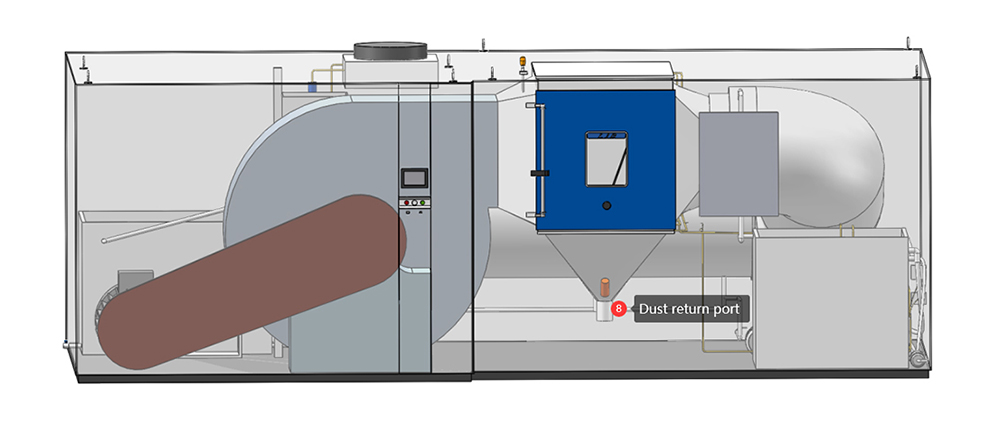

Configuration of Blowing Sand Test Chamber

① Workroom | SUS304 stainless steel plate, can withstand the erosion of high-speed flying sand dust. equipped with temperature sensor, wind speed sensor, concentration sensor. Dust is blown in from the left side of the workroom, and the duct circulates counterclockwise.

|

|

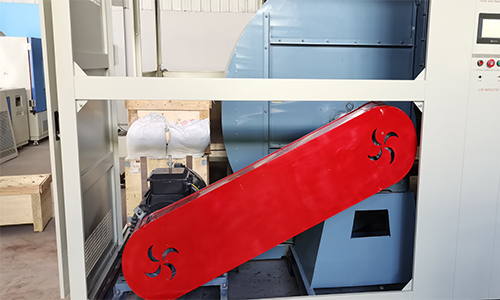

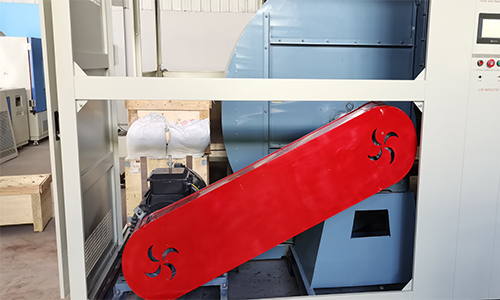

② Centrifugal fan | Make the dust movement, the centrifugal fan blade high-speed operation dust inhalation fan and into the dust pipe, forming a sand and dust environment. |  |

③ Heating tube | The air in the dust sand test chamber is heated to simulate different temperature environments and meet the test temperature requirements in MIL-STD-810 standard. |  |

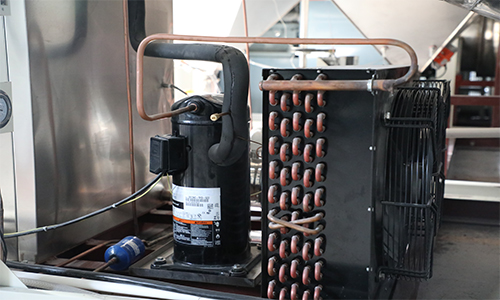

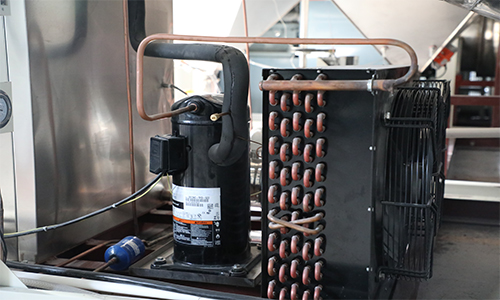

④ Water tank | To cool the air duct, the high-speed flying sand dust and the air duct will rub and generate heat. Water cooling energy saving and environmental protection, cooling speed is fast. |  |

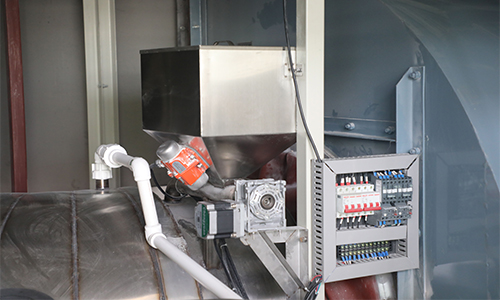

⑥ Pump pully | Connected pump, power source for dust circulation. |  |

⑦ Dust inlet | It is the entrance of dust into the workroom, connected with the dust pipe, and the dust is sent into the Workroom through the dust inlet under the action of the centrifugal fan. |  |

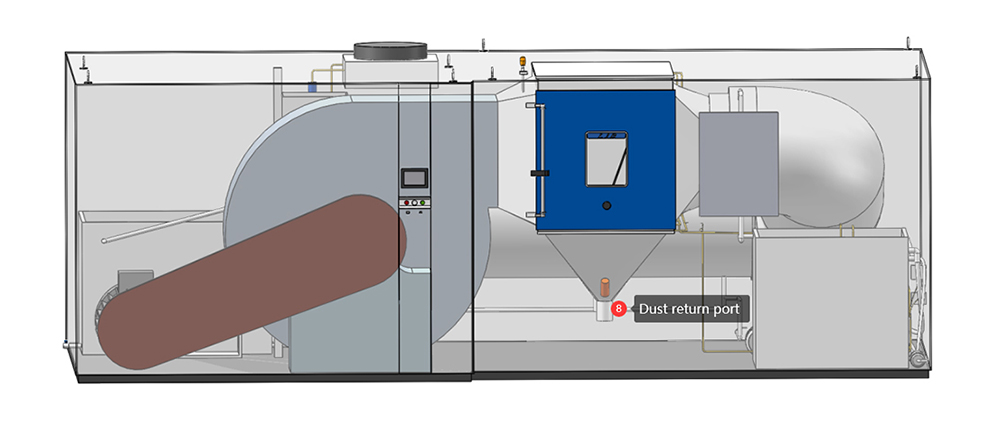

⑧ Dust return port | The tested dust is discharged through the dust outlet or collected for subsequent treatment. |  |

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español