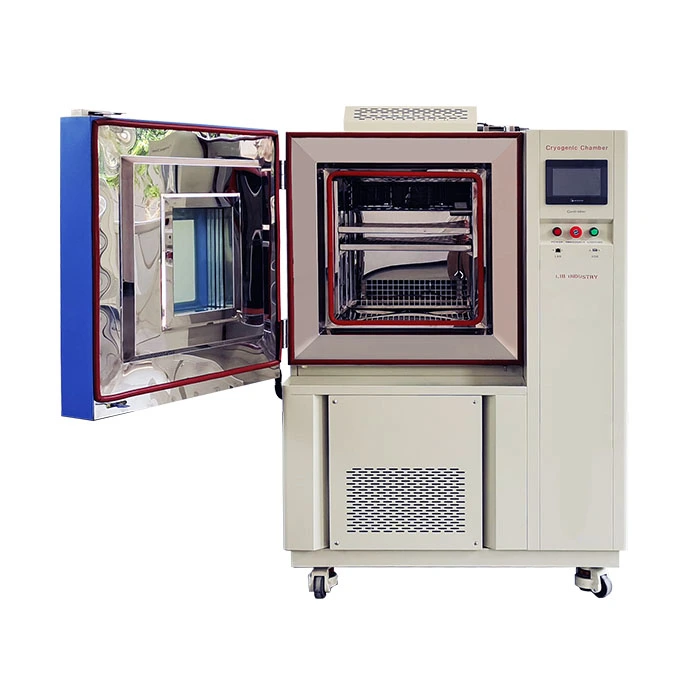

Cryogenic Chamber Features and Benefits

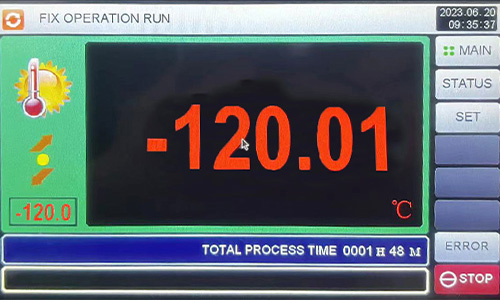

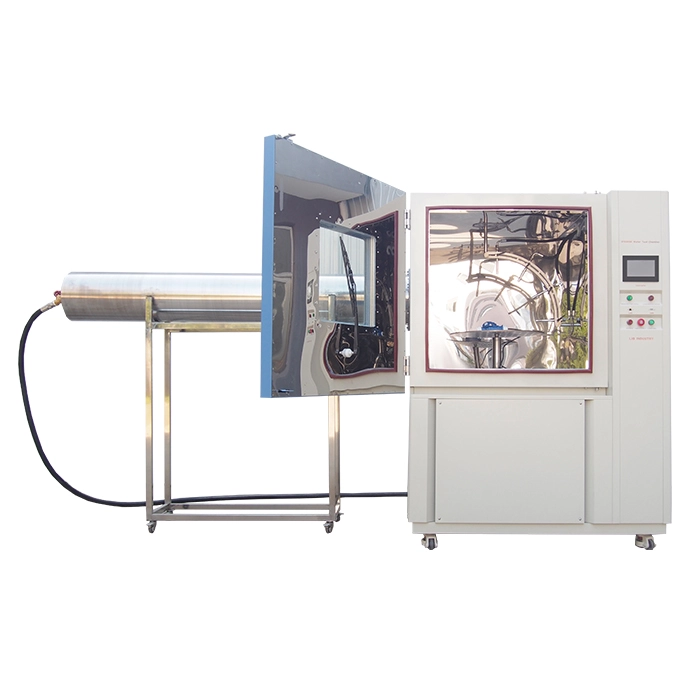

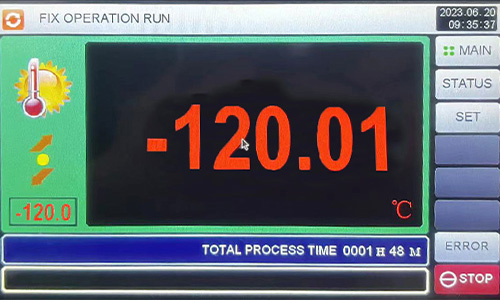

1. Replacing the traditional way of cooling with liquid nitrogen, LIB cryogenic chamber achieves a low temperature condition of -120°C through mechanical refrigeration.

2. The cryogenics chamber refrigeration system is reliable and stable, which can realize the test in a stable cryogenic environment.

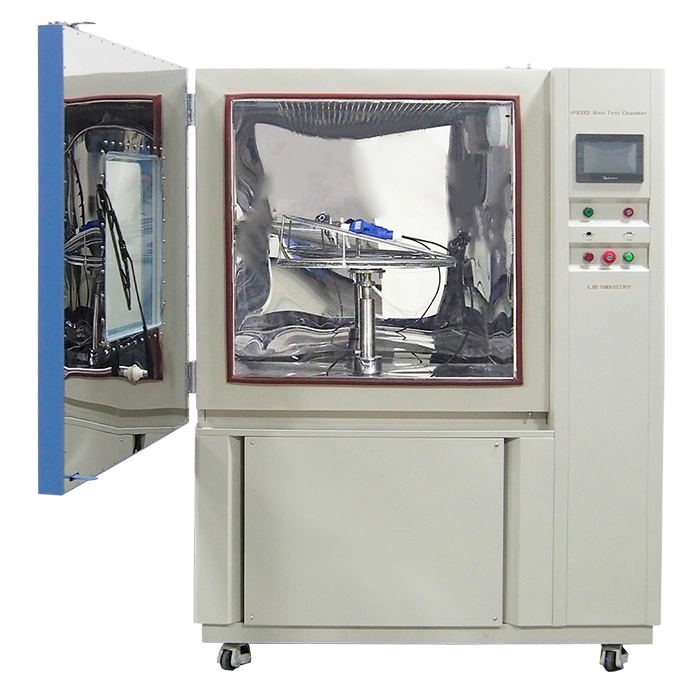

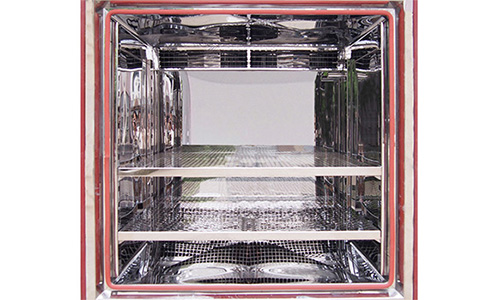

3. The standard cryogenic chamber has 2 sample holders, which can be adjusted and disassembled to test specimens of different sizes. The air circulation system of the test chamber provides good air circulation, achieving good temperature uniformity.

4. The cryogenic chamber applies programmable control, which can realize 120 programs for testing. The cryogenic chamber can be controlled remotely through mobile devices; it can also be connected to the unified control system of the laboratory to achieve unified control and operation.

Cryogenic Chamber Specifications

Model | CF-100 | CF-225 | CF-500 | CF-800 | CF-1000 |

Internal Dimension (mm) | 400*500*500 | 500*600*750 | 700*800*900 | 800*1000*1000 | 1000*1000*1000 |

Overall Dimension (mm) | 900*1050*1620 | 1000*1140*1870 | 1200*1340*2020 | 1300*1540*2120 | 1500*1540*2140 |

Interior Volume | 100L | 225L | 500L | 800L | 1000L |

Temperature Range | -120℃ ~ +150℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Cooling Rate | 1 ℃ / min |

Heating Rate | 3 ℃ / min |

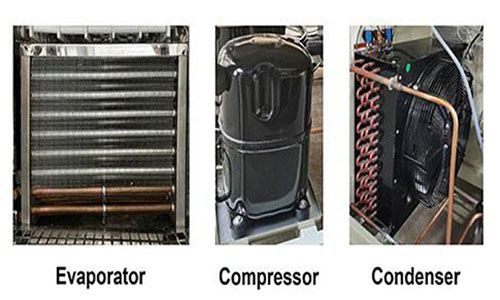

Cooling system | Mechanical compression refrigeration system |

Refrigerating unit | Cascade compressor |

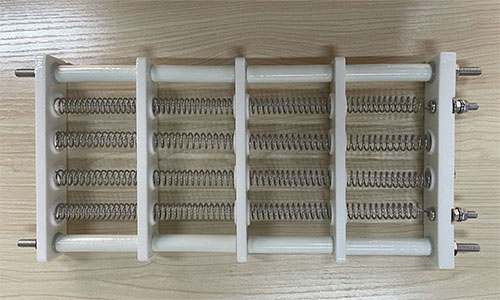

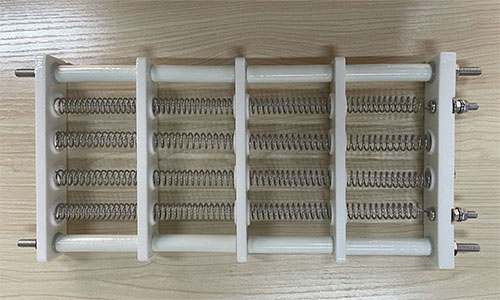

Heating Element | Nichrome heater |

Controller | Programmable color LCD touch screen controller,Ethernet connection |

Safety Device | Over-temperature Protection; Over-current Protection; Refrigerant High-Pressure Protection; Earth leakage Protection |

Exterior Material | Steel Plate with protective coating |

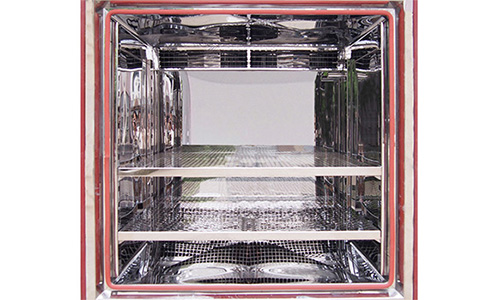

Interior Material | SUS304 stainless steel |

Thermal Insulation | Plyurethane foam and insulation cotton |

Observation Window | Interior lighting, double-layer thermo stability silicone rubber sealing |

Standard Configuration | 1 Cable hole (Φ 50,) with plug; 2 shelves |

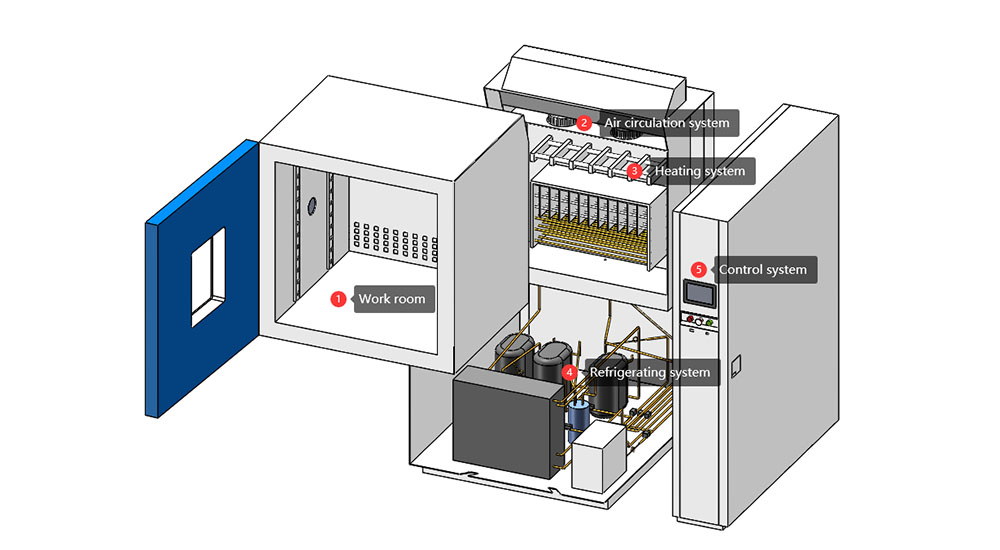

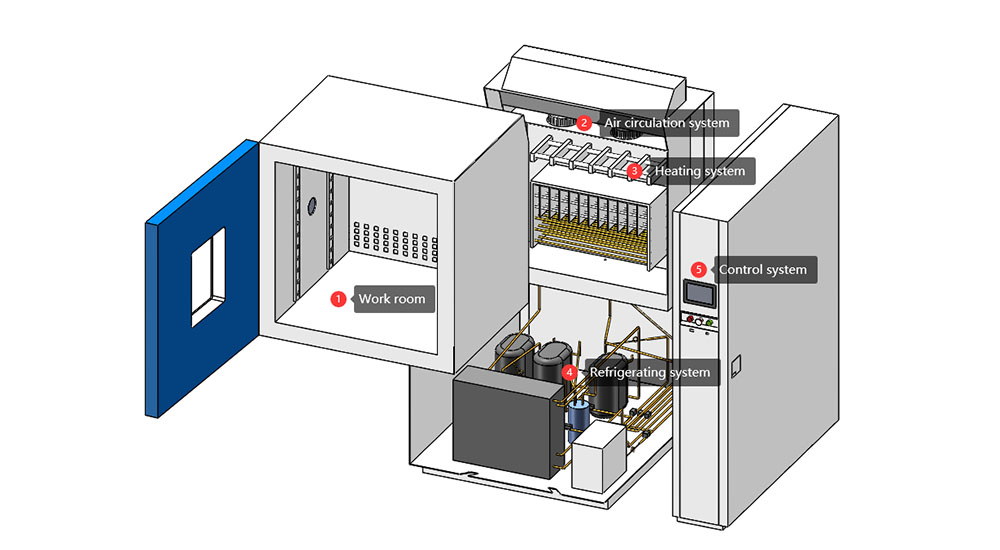

Configuration of Cryogenic Chamber

| ①Workroom | Cryogenic chamber workroom is made of SUS304 which has good high and low temperature resistance.The standard cryogenic chamber is equipped with a double sample holder. Sealing strips and precise sealing structure design prevent cold air leakages. |  |

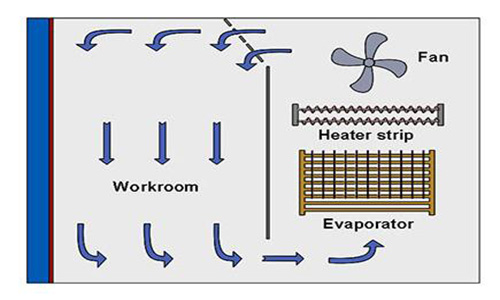

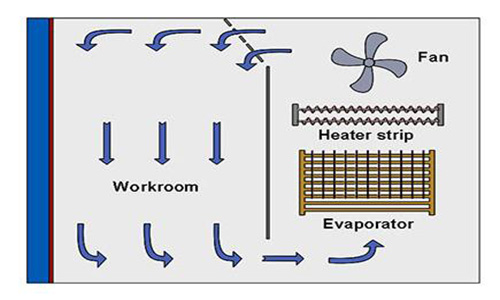

②Air circulation system | Air circulation systems are equipped with high performance fans which encourage air circulation in the workroom. In the cryogenic test, temperature uniformity is a very important indicator, requiring ±2 ° C. |  |

③Heating system | The use of nickel-chromium alloy heating wire, etc., can quickly generate heat, from the cryogenic state to a higher temperature when the heating system needs to play a role. The highest temperature can reach +150℃. |  |

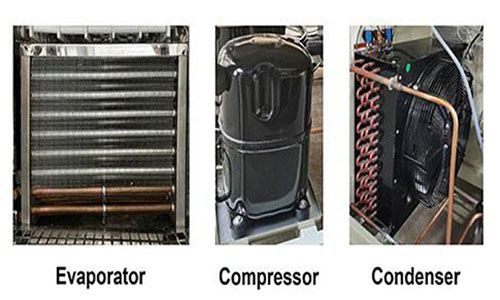

④Refrigeration system | A cascade mechanical refrigeration system is adopted.It is mainly composed of a compressor, a condenser, a throttling device (capillary) and an evaporator to form a refrigeration cycle to control the low temperature to -120°C. |  |

⑤Control system | The heating system and cooling system is controlled by PID algorithm. The control system also has various safety protection functions, such as over temperature protection, compressor overload protection, etc. |  |

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español