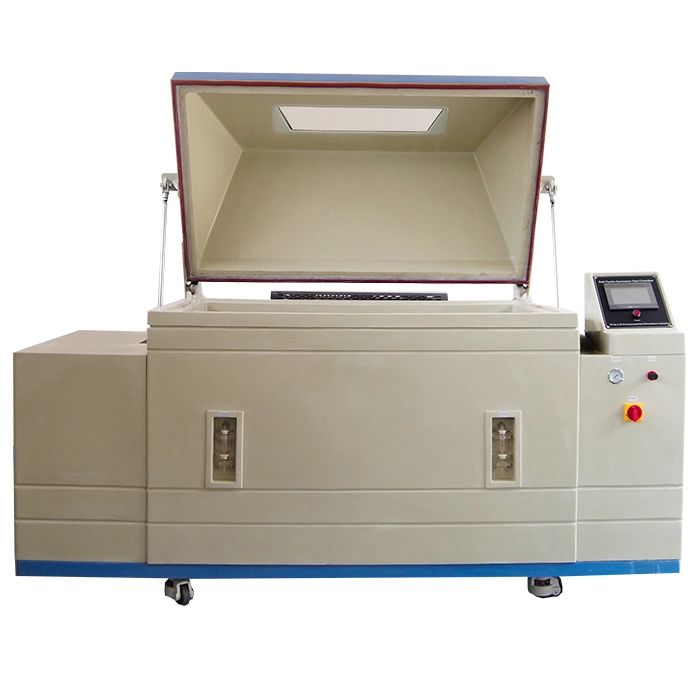

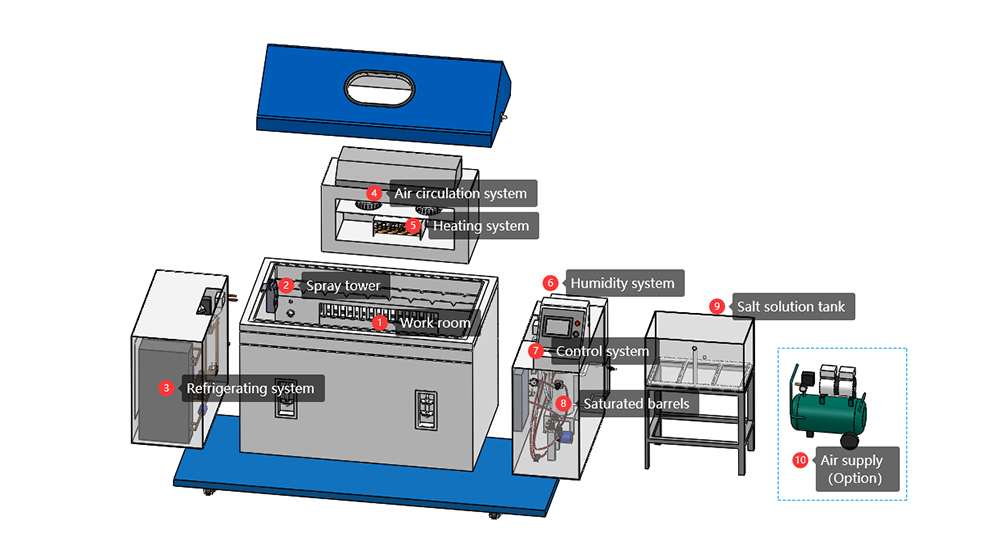

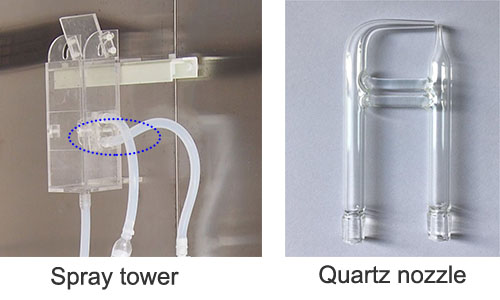

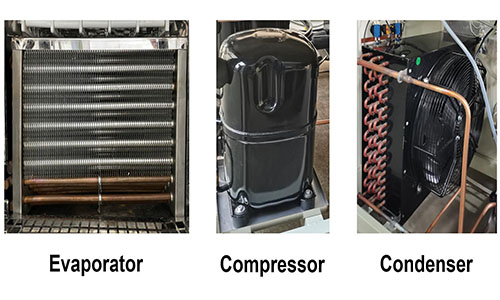

LIB cyclic corrosion test chamber can perform the neutral salt spray, acid salt spray, prohesion and the alternating salt spray corrosion test. These CCT chambers can comply with accelerated corrosion test methods included ASTM B117, ASTM G85, ISO9227, IEC60068-2-52, ISO7253 and many others. NSS, AASS and CASS test can be carried out in the cyclic corrosion fog spray chamber.Cyclic corrosion fog spray chamber reproduces a more authentic salt spray environment with adjustable humidity.

Model: SC-010, SC-016, SC-020

Standard:ASTM D6899, ISO 11997-1, ISO 11997-2, ISO 4628 1~5, SAE J2334, WSK-M2G299, GM4298P, GM4476P, GM 9540P

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español