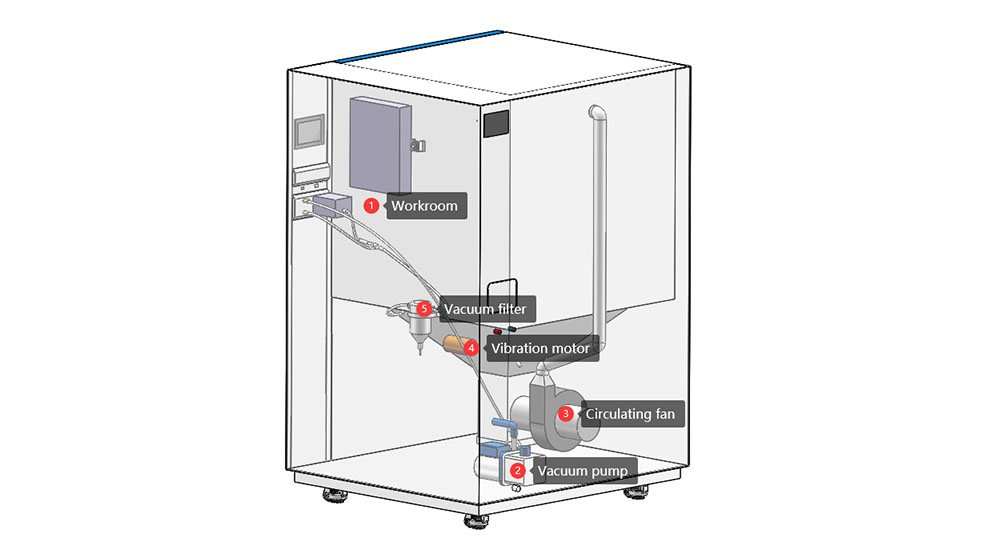

LIB Industry IP Dust Test Chamber simulates the dust environment in line with IEC 60529 IPX5 (to prevent harmful dust accumulation) and IPX6 (to completely prevent dust intrusion) standards, to provide a basis for product design, production process improvement and quality control, to ensure that the product can resist dust intrusion in actual use, normal operation.

Temperature range: room temperature ~ +50℃,

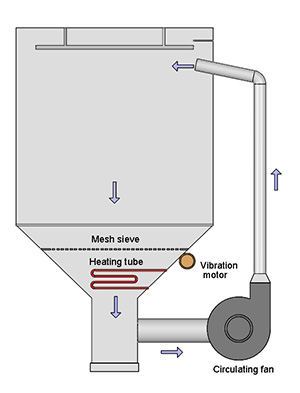

Dust concentration: 2kg/m³-4kg/m³

Dust specification: Talc powder that can be sifted through a square hole with a 75μm sieve and a wire diameter of 50μm.

Model: DI-800, DI-1000, DI-1500, DI-2000

Standard: IEC 60529, IP5X, IP6X, ISO20653, IEC 60068-2-68, IEC 60598, MIL-STD-810G

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español

5.webp)