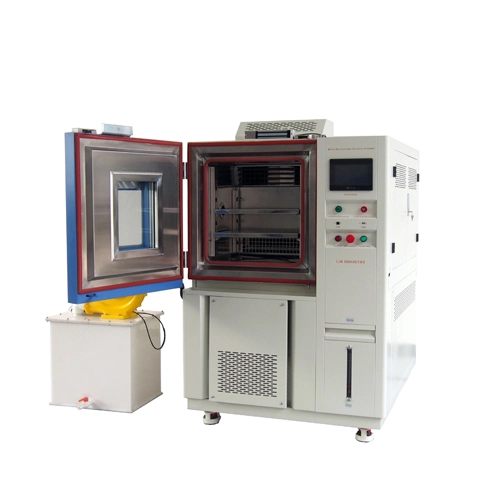

Features and Benefits of Noxious Gas Test Chamber

1. The noxious gas test chamber can achieve comprehensive temperature, humidity and noxious gas test. Both single gas test and multi-gas test are included to meet different test standards such as IEC 60068-2-42, IEC60068-2-60.

2. Noxious gases include SO2, H2S, NO2, NH3, Cl2, etc. The chamber can perform single or multiple gas test.

3. From obtaining customer needs, to discussing solutions, production, transportation, installation and commissioning, LIB Industry can realize one-stop solutions.

4. The corrosive gas test chamber has good sealing. Its exhaust gas treatment device can safely and efficiently process exhaust gases after the test.

Specifications of Noxious Gas Test Chamber

Model | GCM-100 | GCM-225 | GCM-500 |

Internal Dimensions (mm) | 400*500*500 | 500*600*750 | 700*800*900 |

Overall Dimensions (mm) | 1010*1050*1620 | 1110*1150*1860 | 1330*1350*2010 |

Interior Volume (L) | 100 | 225 | 500 |

Temperature Range | 15 ℃ ~ 80 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Humidity Range | 30% ~ 98% RH |

Humidity Deviation | ±2.5% RH |

SO2 Concentration | 100 ~500 ppb± 20 ppb (Adjustable) |

H2S Concentration | 10 ~100 ppb ± 20 ppb (Adjustable) |

NO2 Concentration | 200 ppb ± 20 ppb (Adjustable) |

Cl2 concentration | 10 ~20 ppb ±5 ppb (Adjustable) |

Air Change Rate | 3~10times /h |

Cooling system | Mechanical compression refrigeration system |

Humidifier | External isolation, stainless steel surface evaporation humidifier |

Water Supply System | Water purification system, Automatic water supply |

Controller | Programmable color LCD touch screen controller Ethernet connection, PC Link |

Gas Sensor | H2S/NO2/CL2/SO² gas sensor |

Air Circulation | Centrifugal wind fan |

Door Lock | Electromagnetic lock |

Gas Exhaust Device | Exhaust Unit |

Safety Device | Humidifier Dry-combustion Protection; Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection |

Interior material | SUS316 stainless steel +Glass fiber reinforced plastics |

Exterior material | Steel Plate with protective coating |

Noxious Gas Test Chamber Working Principle

The sample is placed in the workroom and the high-precision flow controller is set to introduce the toxic gases (single, mixed) into the well sealed workroom. Fan device is installed in the noxious gas test chamber to evenly distribute the gas. At the same time noxious gas test chamber can control temperature and humidity, test time, test cycle, etc. Sensors in the workroom are to monitor gas concentration, temperature and humidity. Operator can observe sample changes through window in real time. After the test is finished, the noxious gas was purified and discharged.

Noxious Gas Test Chamber Application

Noxious gas test chamber can perform single gas test in accordance with IEC 60068-2-42, IEC 60068-2-60 and other standards, and can also conduct NO2, CO2, H2S and SO2 mixed gas test. Noxious gas test chamber is widely used in industrial production, automotive, electronics, buildings and other industries which may occur noxious gas.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español