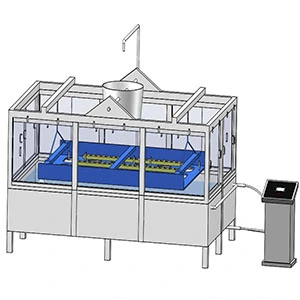

Rainstorm, light rain, snow melt water and other rainfall types, as well as different rainfall angles, rainfall intensity and other conditions.Temperature, rainfall intensity, time, spray angle can be precisely controlled and adjusted.

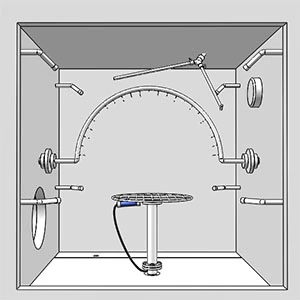

LIB Industry provides a large selection of water spray chambers to test the IPX1, X2, IPX3, IPX4, IPX4, IPX5, IPX6, IPX7 IPX8, IPX6K and IPX9K protection degree against rain and sprays according to IEC 60529, MIL-STD 810 and other international standards.

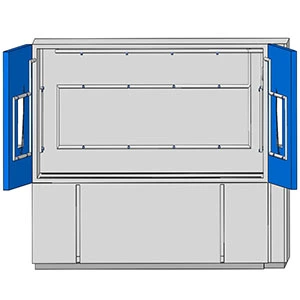

Our Rain test chambers, such as the ipx9k test chamber, are available in different sizes and structures to meet the different testing needs of customers.

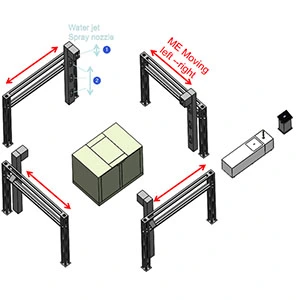

The rain test chamber, a type of environmental test chamber for sale at LIB Industry, is to simulate the natural rainfall environment and test the waterproof performance of the product. Different lines of rain test chamber includes IPX1 IPX2 IPX3 IPX4 IPX5 IPX6 IPX7 IPX8 IPX9K. We also provide walk-in rain test chambers that is large size and can simulate a variety of environmental conditions.

Rainstorm, light rain, snow melt water and other rainfall types, as well as different rainfall angles, rainfall intensity and other conditions.Temperature, rainfall intensity, time, spray angle can be precisely controlled and adjusted.

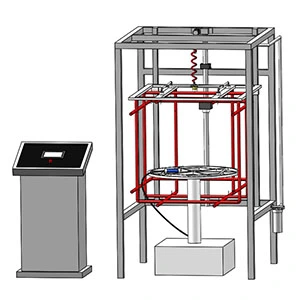

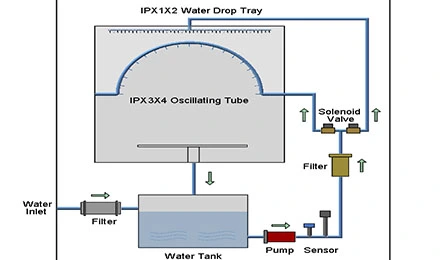

The rain test chamber is equipped with a series of water pipes to form a water circulation system, which can reduce the waste of water resources, and meet the requirements of environmental protection.

LIB specially designed a set of automatic inlet filtration system to filter impurities in 0.03mm particles, which ensures the smooth flow of the spray system.

Solenoid valve equipped in the water system of the test chamber, and adjust the water flow by controlling the switching frequency and opening of the solenoid valve, so as to achieve higher flow control accuracy and stability.

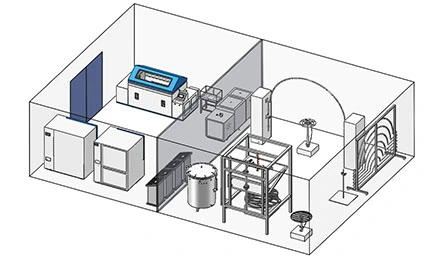

Build a new, personalized IP lab based on your needs.Various types of rain test chamber comply with ISO 20653, IPX1K to IPX6K, IPX1 to X9K, SAE J 575, JIS D 0203, GMW16001, MIL STD 810 and other standards.

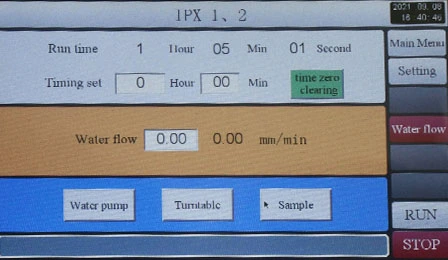

Advanced PID control system, 12 languages are available.LCD displays test conditions (including rainfall intensity, time, spray angle, etc.).

Calibration and accuracy are crucial aspects of rain test chambers to ensure reliable and repeatable test results. Calibration involves verifying and adjusting the performance of the chamber to align with established standards and specifications. Precise calibration is necessary to ensure that the rain test chamber accurately simulates real-world weather conditions.

To maintain accuracy, rain test chambers typically undergo regular calibration checks using traceable reference devices, such as calibrated rain gauges or flow meters. These devices measure the water flow rate and intensity within the chamber, which can be compared against the desired test parameters.

The calibration process includes adjusting factors such as water flow rate, drop size, and distribution patterns to ensure consistency and accuracy. Additionally, the chamber's sensors, control systems, and data acquisition equipment should also be periodically calibrated to ensure their accuracy in measuring and recording test parameters.

Regular maintenance, cleaning, and calibration of the rain test chamber are essential to ensure accurate and reliable test results, especially for ip x3. Adhering to calibration procedures and good laboratory practices helps to minimize errors and uncertainties in rain testing, providing confidence in the results obtained from rain test chambers.

LIB Industry rain chamber is to simulate the natural rainfall environment through a series of systems and processes, so as to effectively test the rain resistance of the product. Its core components include rainfall system, water supply system, control system, sample fixtures and water circulation system. When rain test chamber works, the controller starts the water supply system according to the pre-set parameters, and the water is delivered to the rain or water jetting and the tested sample receives the specified time and intensity of the rain on the turntable.

1. Sensor Calibration: If the test results are inconsistent or erratic, check the calibration of the chamber's sensors, such as rain intensity or drop size sensors. Recalibrate or replace them if necessary.

2. Water Supply Issues: Inspect the water supply system, including hoses, valves, and filters. Ensure there are no blockages or leaks that may affect the water flow rate or distribution.

3. Control System Check: Verify the settings and programming of the chamber's control system. Ensure that the selected test parameters, such as rain intensity or duration, are properly configured.

4. Leakage Detection: If water is leaking from the chamber or seeping into unwanted areas, carefully inspect the chamber's seals, gaskets, and doors. Replace any damaged or worn components to prevent water leakage.

5. Electrical Connections: Check all electrical connections, including power supply, cables, and connectors, to ensure they are secure and properly grounded. Loose or faulty connections can cause erratic behavior or system failures.

6. Software or Programming Errors: If the rain test chamber is controlled through software, check for any errors or glitches in the programming. Update or reinstall the software if needed to address any issues.

7. Safety Features: If any safety features, such as emergency stop buttons or safety interlocks, are not functioning correctly, troubleshoot the system to ensure the operator's safety during testing.

8. User Manual and Technical Support: Consult the user manual provided by the manufacturer for troubleshooting guidance. If needed, reach out to the manufacturer's technical support team for assistance with more complex issues.