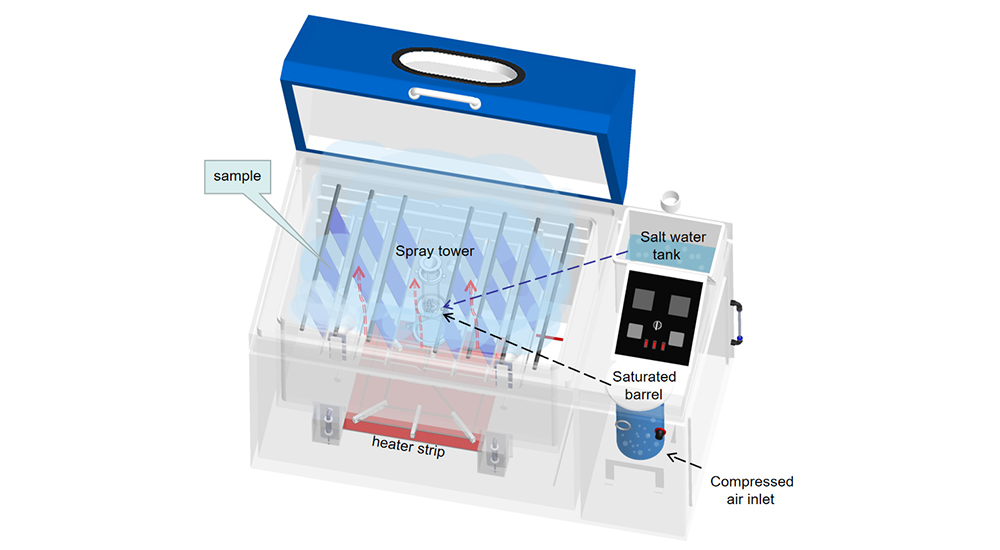

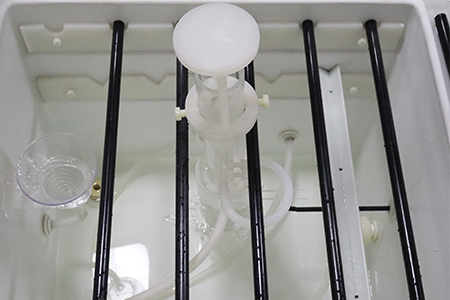

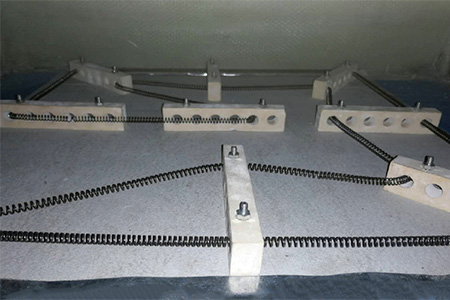

LIB salt spray chamber simulates the salt fog marine climate, is used in the salt spray corrosion test for accelerated corrosion performance of plating and coating on metal surfaces. The salt spray test is divided into two types: neutral salt spray and acid salt spray. A variety of sizes and models of salt spray test apparatus are available for customers to choose.

Model: S-150,S-250, S-750, S-010, S-016, S-020

Standard: ASTM B117, ISO 9227, ASTM G85, D17 2028, SAE J2334, ISO4611, ISO7253, BS3900-F12, IEC 60068-2-11, DIN 50021, ASTM G85-02e1 Annex A1,BS 7479, ASTM B368

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español