UV Test Chamber Features and Benefits

1. UV-SI-260 is widely used in UV aging test, which can realize the comprehensive test of UV, temperature, humidity and water.

2. The uv aging test equipment is equipped with 8 UV lamps, and the current of the lamps can be displayed, mainly to display the service life of the lamps, which is convenient for users to replace the lamps in time. UVA-340,UVB-313,UVB-351 are all supported. UV lamp power is 40W.

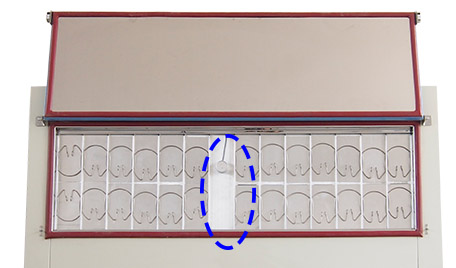

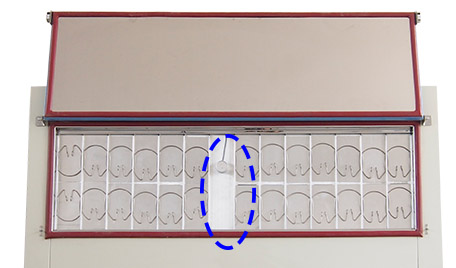

3. The specimens of the uv aging machine are easy to install, and 52 pieces of 75*150mm specimens can be put in at one time.Customized sample holder is also designed for irregular test pieces.

4. All uv weathering test chambers are CE and RoHS certified.

UV Test Chamber Specifications

Model | UV-SI-260 |

Internal Dimension (mm) | 450*1170*500 |

Overall Dimension (mm) | 610*1330*1470 |

Specimen Holder Size(mm) | 75*150 |

Specimen Capacity | 56 Pieces |

Irradiation Source | Fluorescent UV lamps (8) - 40 W |

Temperature Range | Ambient ~ 90 ℃ ±2℃ |

Black Panel Temperature (BPT) | 35 ~ 80 ℃ |

Humidity Range | ≥95% RH |

Bandwidth | 290 ~ 400nm |

Irradiance Control | 0.3~20 W/㎡ |

Water Spray Cycle | 1~9999H59M (Adjustable) |

Distance of Specimen and lamp | 50mm |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Water Supply System | Automatic water supply, Water purification system |

Safety Device | Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection; Phase Sequence Protection |

Exterior Material | Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

UV Test Chamber Application

UV spectra is a part of sunlight spectra, causing damage to test pieces. All the specimens needed to be under UV light radiation can be tested in the UV test chamber. For example, plastics, rubber, coatings and etc. in automotive industry, aerospace, building materials. UV testing chambers, as a type of uv accelerated weathering tester, are also widely used in scientific laboratory conducting research on material aging and photochemistry.

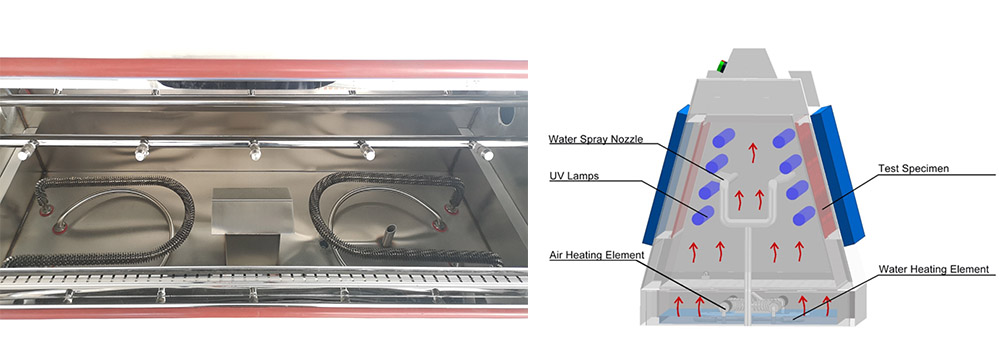

Configuration of UV Test Chamber

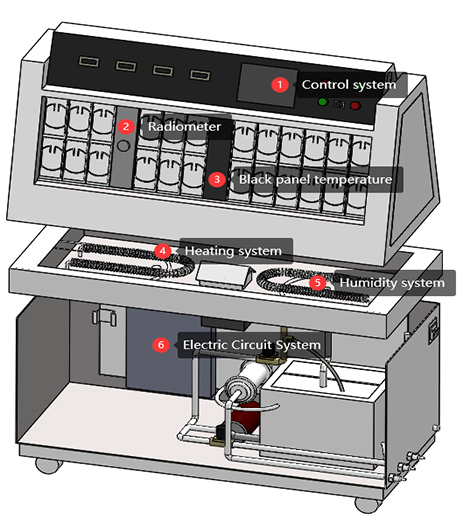

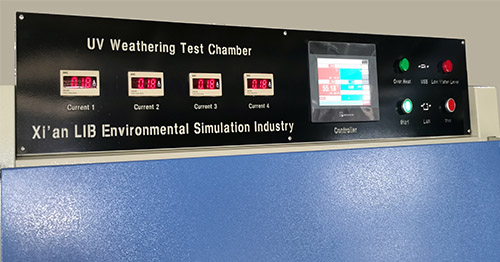

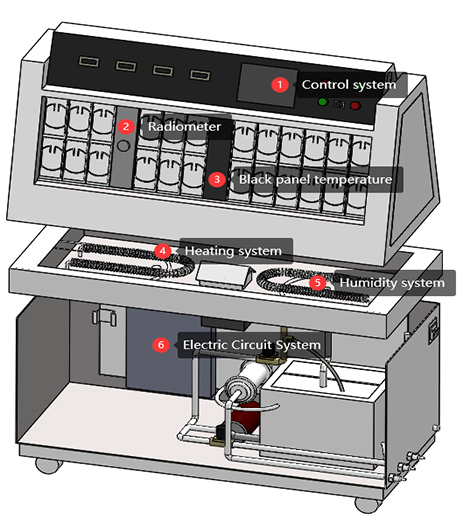

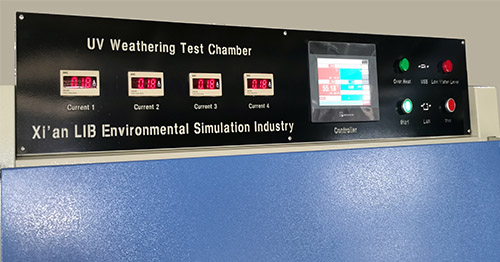

①Control system

In order to find the UV lamp failure or light source decay in the first time, UV test chamber is equipped with four current display devices on control system to remind the experimentered in real time.

②Radiometer

The radiometer is equipped with probes in a specific wavelength range 290-400 nm.

③Black Panel

Black panel temperature equals the temperature transmitted by hot air (working room) + The temperature produced by irradiation by a light source.

④Heating system

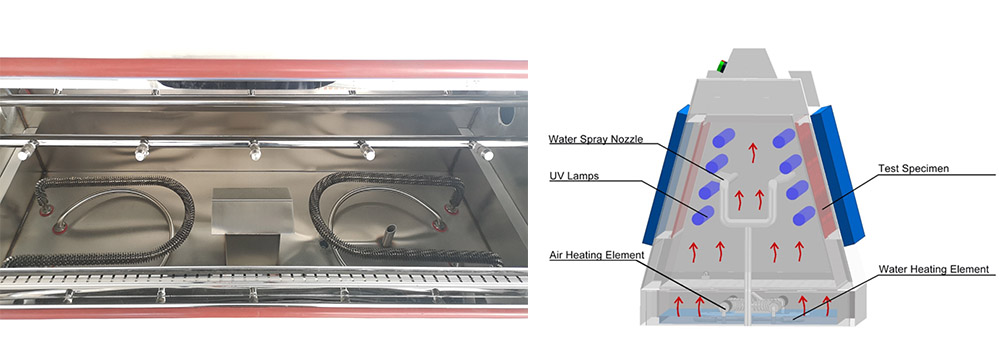

There are two kinds of heating tubes at the bottom of the workroom, U-shaped heating tube to heat the workroom, circular heating pipe to heat the water, and a fan under the middle air duct to blow the heating moisture upward.

⑤Humidity system

The heating tube is immersed in water, which is heated to form steam to humidify the workroom.

⑦Spray Nozzle

Water spray pipe is equipped with ten nozzles, the diameter of the nozzle is 0.5mm, the settlement is 0.8 ~ 1.0mm / 80cm2 / H, and the flow rate is 0.3L / min, which simulates outdoor moisture damage to the material.

How to Choose Proper UV Test Chamber?

• Specify what kind type of uv aging test to be performed, based on your sample size and quantity, and the required test standards and specifications.

• Different types of UV lamps are suitable for different test purpose. UV test chamber usually uses fluorescent ultraviolet lamp as light source such as UVA-340, UVB-313 and so on.

• If you need to simulate the combined environment conditions such as uv light damage with rain corrosion, the uv light test chamber with spray function, you can set spray time, spray cycles.

• UV test chambers from professional environmental chamber manufacturers with crediable after-sales service can ensure attain real-time and professional help.

LIB Industry UV Test Chamber Working Principle

The working principle of UV test chamber is to use fluorescent uv lamp as the light source, through the simulation of ultraviolet radiation in the natural sunlight, the sample in the workroom will be exposed to the ultraviolet radiation, to accelerate the aging process of the material. By testing and analyzing the properties of the samples before and after the test, the performance of weatherability, durability and color change of the materials can be evaluated. The UV aging test chamber can control the temperature, humidity, light intensity and other parameters to ensure the accuracy and reliability of the test.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español