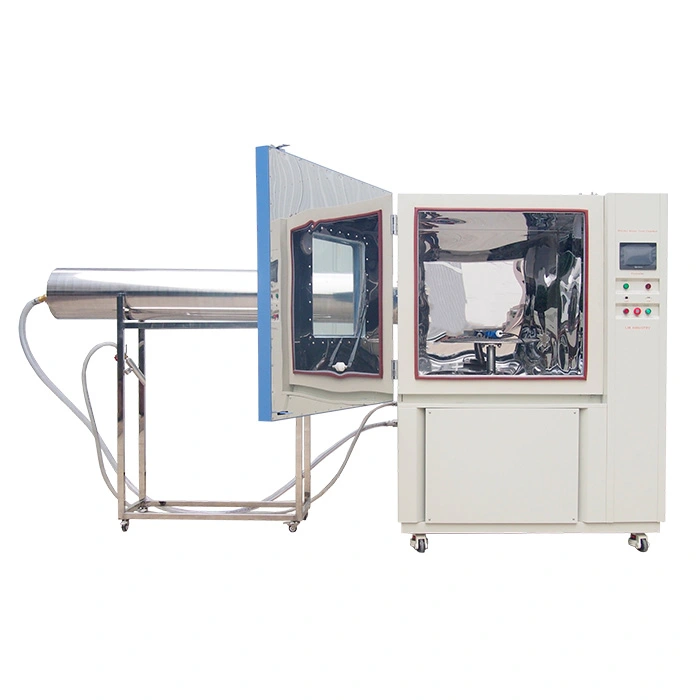

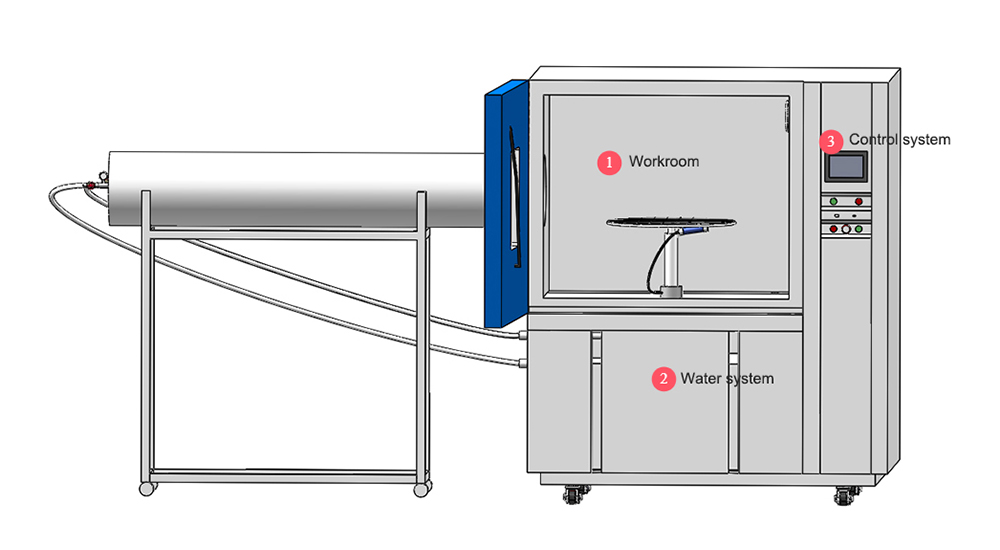

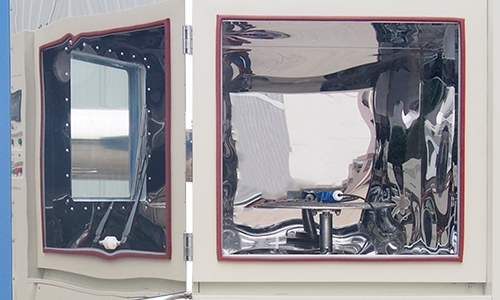

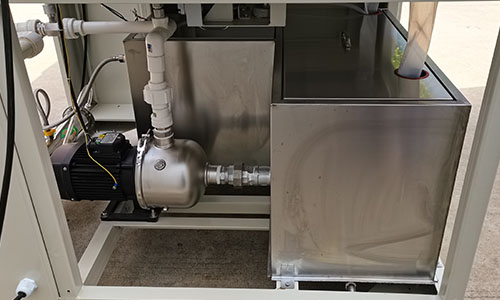

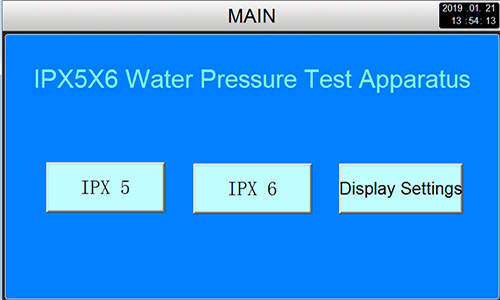

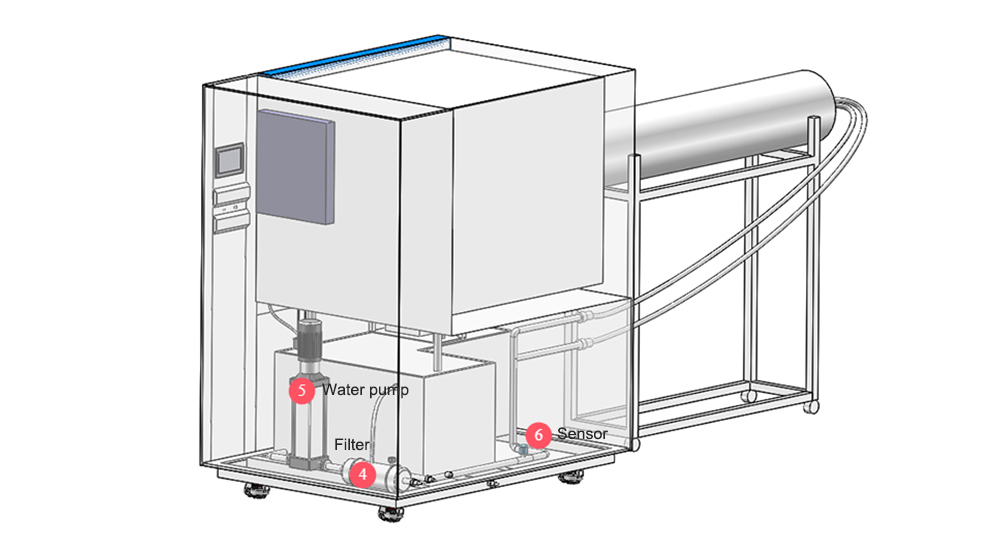

LIB Water Spray Jetting Chamber is used for the ingress protection tests involves immersing the equipment under test (EUT) according to IEC60529 standard IPX5 X6 rate. This water jetting chamber is suitable for IP66, IP54 testing. Water is sprayed from IP5X and IP6X nozzles, and the flow rate is controlled by electromagnetic flowmeter.

Model: R56-800, R56-1000

Standard: GJB 150.8-86, ISO 20653, IEC 60529, UL 50E, UL 1598, UL 153, UL1573, UL 60950-1, IPX5, IPX6

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español