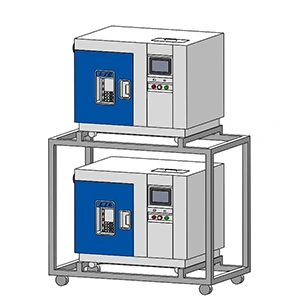

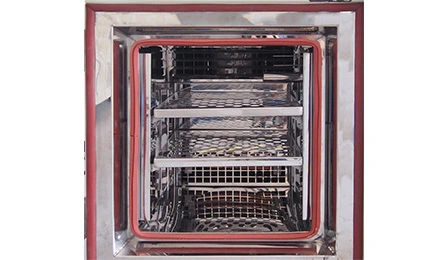

The benchtop environmental test chamber is small in shape, does not take up too much space, with an internal capacity of 50L and 80L. Supports stacking to meet the requirements of multiple devices at the same time.

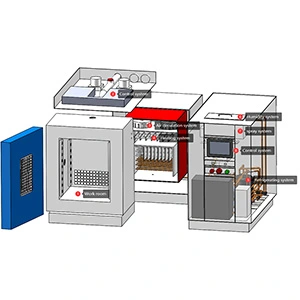

LIB Industry Benchtop Test Chambers are available as standard models and can also be customized, coming in a range of sizes and performance levels. A benchtop environmental test chamber is a compact environmental test chamber for sale at LIB Industry, saving laboratory space while providing reliable testing capabilities. For temperature, benchtop test chamber can be adjusted from - 70 °C to +150 °C with three low temperature. Regarding humidity, it can also regulate humidity levels from 20% RH to 98% RH. Besides rapid temperature - change capabilities for thermal shock testing can be achieve equipped with advanced data - logging systems to record test parameters and results accurately for further analysis.

Benchtop environmental test chamber is widely used in the research and development, production and quality control of electronics, medicine, materials, automotive and other industries.

The benchtop environmental test chamber is small in shape, does not take up too much space, with an internal capacity of 50L and 80L. Supports stacking to meet the requirements of multiple devices at the same time.

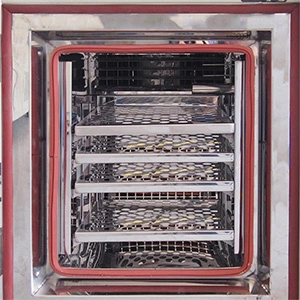

The PT-100 Class A sensor has an accuracy at 0.001 degrees.A wet gauze converted by temperature difference, showing real-time relative humidity. The temperature fluctuation is controlled at ≤ ±0.5 ° C, and the humidity deviation can be maintained at ±2.5 ° C.

The manufacturing cost of the benchtop environmental test chamber is relatively low, and because of the small size and low power, the energy consumption is less, which can save energy consumption and reduce the use cost.

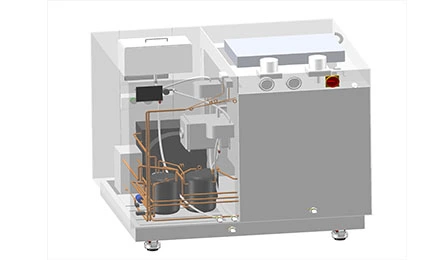

A variety of safety protection devices, such as over-temperature protection, compressor overload protection, leakage protection, water shortage protection, etc.

External Materials is 4mm A3 steel panel with 2mm protective coating, the internal material is SUS 304 stainless steel, mirror surface, rust-proof to high and low temperature and moisture corrosion; Polyurethane rigid foam material as the middle insulation material.

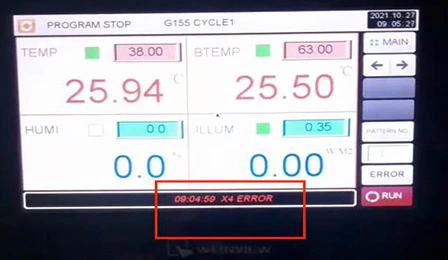

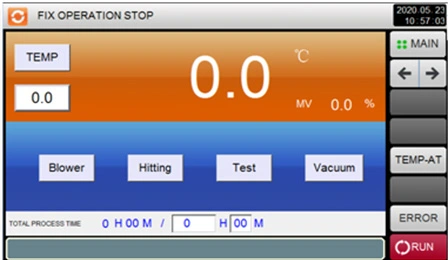

Advanced PID control system, 12 languages are available.LCD displays test conditions (including dust concentration, wind speed, temperature, etc).

1. International Standards:

IEC 60068-2-1: It is the International Electrotechnical Commission's standard for low-temperature testing of electrical and electronic products, which is widely recognized in the world. If the small benchtop environmental test chamber is used for export or to participate in the test of international projects, it needs to meet the standard.

IEC 60068-2-78: It is the international standard for constant wet heat test, and has a guiding role for wet heat test of small bench environmental test chamber.

IEC 60068-2-30: specifies the method and requirements of alternating humid heat test, and the small bench environmental test chamber should refer to this standard when performing alternating humid heat test.

2. Industry standards:

Different industries may have their own industry standards, such as the electronics industry, the automotive industry, the aerospace industry, etc., and there will be some specific requirements and standards for the use of benchtop environmental test chambers. These industry standards are usually developed on the basis of international standards, combined with the characteristics and needs of the industry.

The lifespan of a benchtop test chamber is influenced by multiple factors, such as the manufacturing quality, how it is used and maintained, and the materials it is made of. If a chamber is well - manufactured and properly maintained, it can be in use for as long as 10 years or even more.

1. Follow the operation manual

The operator shall strictly follow the operation manual provided by the manufacturer. In the process of starting up, setting test parameters, and shutting down, follow the prescribed steps to avoid damage to the device due to misoperation. For example, when setting parameters such as temperature and humidity, ensure that the input value is within the rated range of the device.

2. Arrange test tasks reasonably

Avoid overuse. Running the test chamber continuously for a long period of time will accelerate the wear of equipment components. Reasonably plan the test task, and give the equipment appropriate rest time after continuous operation for a certain period of time, for example, stop for 30 minutes to 1 hour after every 8-12 hours of operation.

Select the appropriate test mode according to the test requirements. Do not force the test in a mode that the equipment is not suitable for, such as for a test chamber that does not have a special extreme environment simulation function, do not attempt to carry out tests beyond its capacity.

1. Cleaning

Clean the inside and outside of the test chamber regularly. Internal dust and debris may affect the heat dissipation of the device and the accuracy of the sensor. Use a clean wet cloth to wipe the interior, remove dust, water vapor condensation, etc. For corners that are difficult to clean, small cleaning tools can be used to assist. The exterior should also be kept clean to prevent dust from clogging the vents.

2. Check component connections

Check regularly whether the various components of the test chamber are connected tightly. Such as power cables, sensor connection cables, heating and cooling system pipeline connection. Loose connections may result in poor contact, affect the normal operation of the device, and even cause electrical failures.

3. Maintain the cooling system

The refrigeration system is a key part of the test chamber. Check the pressure and content of the refrigerant regularly. If the pressure is abnormal or the refrigerant is insufficient, contact professionals in time to supplement or repair. At the same time, keep the radiator of the refrigeration system clean to ensure a good heat dissipation effect.

4. Calibrate the sensor

The accuracy of the temperature and humidity sensors is crucial to the test results, especially for humidity chamber benchtop. The sensor is calibrated regularly to ensure the accuracy of its measurements. Standard calibration equipment can be used to calibrate according to a specified period (such as every 3-6 months).

1. Place environment

Place the test chamber in a suitable environment. Avoid placing in direct sunlight, damp, dusty or strong vibration places. The ideal ambient temperature for placement should be maintained at 15-35 ° C and the relative humidity at 40%-70%.

Ensure that there is enough space around the test chamber for easy ventilation and heat dissipation. Generally speaking, a space of at least 30-50 cm should be left around the test chamber.

2. Power environment

Provide stable power supply. Unstable power supply, such as excessive voltage fluctuations, may damage the electrical components of the test chamber. A voltage regulator can be used to stabilize the power supply voltage and ensure that the input voltage is within the rated voltage range of the test chamber (generally ±10% of the rated voltage).

Xi’an LIB Industry is one of professional environmental chamber manufacturers with a unique brand, and also is the market leader in production, design and sales. LIB will provide the suitable environmental chambers and solutions according to your requirements. Standard models or customized models are all available.

Arrange production according to the designed parameters. After the test chamber is completed, we conduct performance testing, functional inspection, commissioning test, calibration, and issue reports on every step to guarantee quality.

LIB’s professional transportation team carries out international transportation for you, our complete transportation system can achieve door-to-door services. LIB will send professional engineers to provide on-site service for installation services and training.