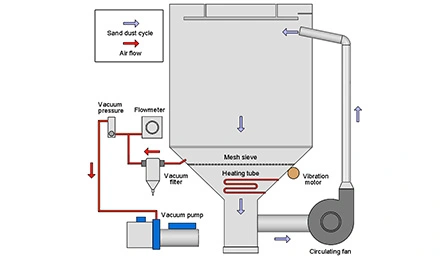

Vertical circulation air blows dust to the workroom, forming a dust circulation system, dust recycling, but also reduce unnecessary operating steps.

IP test equipment namely ingress protection test equipment is a used to test the product shell protection level. LIB Industry IP test equipment is a specially designed test equipment to determine the protection of the product against the invasion of solid objects (such as dust, sand, etc.) and liquids (such as water).

IP test equipment is widely used in many fields such as electronics, electrical, communication, automotive, aerospace, industrial manufacturing and so on. Through the IP level test, it can ensure that the product can still operate normally in a variety of harsh environments, and improve the reliability and security of the product.

For example, for electronic equipment used outdoors, such as street lights, surveillance cameras, etc., it is necessary to have good waterproof and dustproof performance to prevent failure due to environmental factors. The IP test equipment, a type of environmental test chamber for sale at LIB Industry, accurately assesses whether these products meet IEC 60529 and other appropriate standards.

IP test equipment includes two types of dustproof and waterproof test chamber which is in accordance with IEC60529 , ISO20653, IEC 60068-2-68, ASTM and MIL standards.

Vertical circulation air blows dust to the workroom, forming a dust circulation system, dust recycling, but also reduce unnecessary operating steps.

The door body seal is made of double-layer rubber that is resistant to aging and wear, and is equipped with electromagnetic lock to strengthen the seal, prevent misoperation in the test, and ensure the safety of operators and the cleanliness of the workroom.

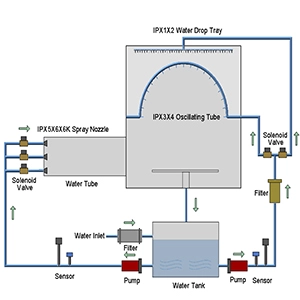

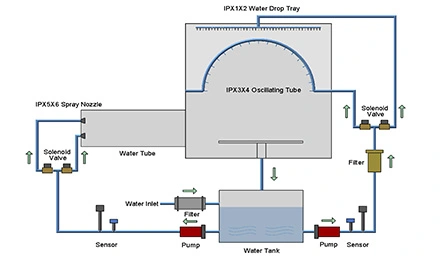

LIB specially designed a set of automatic inlet filtration system to filter impurities in 0.03mm particles, which ensures the smooth flow of the spray system.

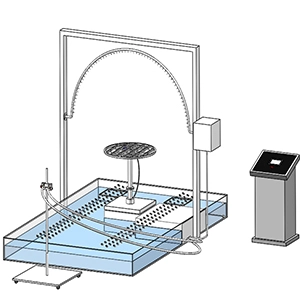

A series of water pipes are arranged in the rain test box to form a water circulation system, which greatly reduces the water consumption.

A variety of rain modes can simulate various natural rainfall scenes such as dripping, drenching, splashing, spraying, etc.

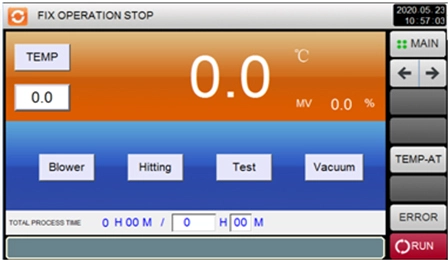

Dust filling time, dust blowing time, temperature and humidity control can be programmed through the PID touch screen controller for automatic operation.

First of all, the protection level of the dust test chamber in LIB Industry IP test equipment is IP 5X and IP 6X dust test. The first characteristic number 5 is required to be dust-proof, that is, not completely prevent the entry of dust, but the amount of dust entering should not interfere with the normal operation of the equipment or affect the safety of the equipment. The first characteristic number 6 requires tight dust protection, that is, no dust is entered.

According to the test requirements, the lower dust class test is not necessary to perform, obviously a higher protection class of the case can meet the lower dust class test.

The dust test chamber in LIB Industry IP test equipment uses talc to simulate the dust environment, and the talc used is required to be able to pass through a square hole filter with a nominal line diameter of 50 μm and a nominal spacing of 75 μm. 2 kg of talc is used per cubic meter of the capacity of the test chamber. The use of talc powder will not exceed 20 tests.

Water spray test chambers in LIB IP test equipment includes a whole set IP rain test

The second characteristic number specifies the protection level of the water

1 is the protection of vertical falling water droplets.

2 is when the shell is tilted upward by 15 degrees, the protection of vertical falling water droplets means that when the shell is tilted upward by 15 degrees from either side.

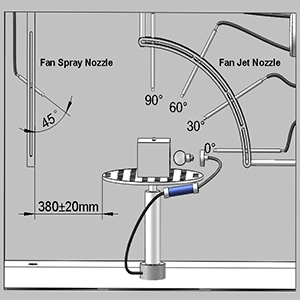

3 is the protection of splashing water from the vertical direction to any side until 60 degrees,

4 is the protection of spray water from any direction to the housing has no harmful effect

5 is the protection of the spray gun from any direction to the housing

6 is the protection of the high-pressure water gun, the high-pressure water gun from any direction to the housing

7 is the protection of the temporary soaking effect, when the housing is under the standard pressure and time conditions

8 is the protection against the effects of continuous immersion, the condition will be harsher than the condition of the characteristic number 7

1. Daily cleaning

1) After each use, the water stains, dust and debris inside the test chamber should be cleaned.

2) Clean the water tank regularly to remove dirt and sediment to ensure clean water quality and prevent nozzle blockage.

3) Clean sprinkler heads and spray pipes to ensure smooth water flow. For clogged nozzle, you can use a soft needle or toothpick to unclog.

2. Check components

1) Check the door seal gaskets of the test chamber weekly for damage, aging, or deformation. If there is any problem, it should be replaced in time to ensure the tightness of the test chamber.

2) Check electrical connections for looseness, damage, or aging. Ensure that the wiring is firmly connected and there is no risk of short circuit.

3) Regularly check the operation of power components such as pumps and fans, and observe whether there is abnormal noise, vibration or overheating. If there is any abnormality, it should be repaired or replaced in time.

3. Regular maintenance

1) Add appropriate amount of lubricating oil to the mechanical moving parts of the test box every month, such as guide rails, lead screws, etc., to reduce wear and ensure smooth movement.

2) Check and calibrate the control system of the test chamber every quarter to ensure that the parameters are set correctly and the sensor works normally.

3) Perform a comprehensive maintenance of the test chamber once a year, including checking the refrigeration system (if applicable), heating system, air duct, etc., and cleaning up accumulated dust and debris.

4. Water quality management

1) Clean water should be used in the industrial rain test chamber to prevent pipe blockage.

2) For the test chamber that is not used for a long time, the water in the tank should be emptied to prevent the growth of bacteria and algae.

5. Storage precautions

1) If the test chamber is not used for a long time, it should be placed in a dry and well-ventilated environment and covered with a dust cover to prevent dust from entering.

2) Before storage, ensure that the inside of the test chamber is clean and all components are in normal condition.

6. Calibration and verification

1) In accordance with the specified time interval (usually one year), ask professionals to calibrate and verify the performance indicators of the test chamber to ensure that it meets the relevant standards and test requirements.

2) Calibration and verification include temperature, humidity, spray pressure, flow and other parameters.

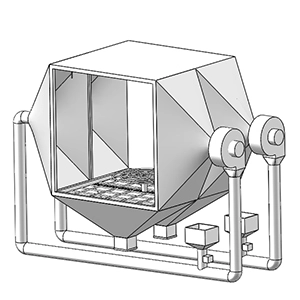

1. Shell material: usually stainless steel, with good corrosion resistance and strength, the design of the shell is usually in line with international standards to ensure the long-term stable operation of the test chamber and good sealing of the studio.

2. Water tank: used to store test water, equipped with water level monitoring and automatic refill device to ensure sufficient water during the test.

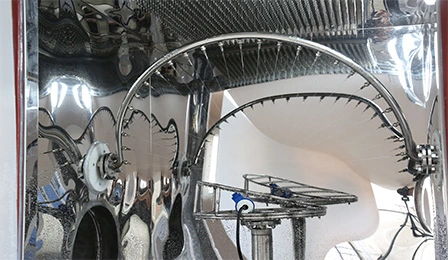

3. Sprinkler head: according to different waterproof test levels, equipped with different types and specifications of sprinkler heads, such as pendulum nozzle, high pressure water nozzle, etc. A rotating turntable is placed in the working room, and water can be evenly sprayed on the surface of the test piece. The waterproof power connector in the work room energizes the test piece and restores the most realistic test conditions.

4. Air duct: used to generate uniform air flow to ensure the uniform distribution of dust particles in the test chamber. Vertical circulation air blows dust to the studio, forming a dust circulation system.

5. Control system: LIB Industry IP test chamber is equipped with advanced control system, which can realize accurate control and adjustment of parameters such as temperature, water output and dust output in the test chamber. The control system can also realize the setting and automatic control of various test modes.